Q. What are some of the pros and cons of using automatic air spray guns versus rotary bell atomizers for robotic painting?

A. There are considerable differences in how air spray guns and rotary atomizers function and are utilized on robots for automated finishing operations. Each atomizer type has specific performance capabilities based on manufacturer, model type and design; therefore, the answers here are more of a general comparison.

Featured Content

Air atomized spray guns are mature applicators, well-known and widely accepted in all industries, except perhaps the OEM auto and truck industry, where rotary bell atomizers are used almost exclusively. There is less information and shared experience available regarding the use of rotary bells in industry segments outside of automotive.

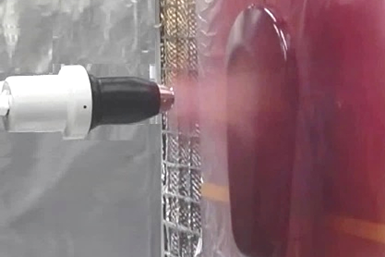

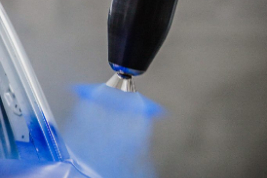

How each type applicator atomizes paint is worthy of consideration. All photos courtesy of Dürr Systems Inc.

Ordinarily, rotary bell atomizers are well known for coating large, flat surfaces because they produce large spray patterns using electrostatics. However, in recent years, more specialized rotary bell atomizers have been developed that produce narrow patterns to coat smaller, more complex geometries, and some function without electrostatics. This is the same technology used for painting auto body interiors, such as door jams and engine boxes.

Air spray guns are obtainable in a variety of nozzle/air cap configurations, which inherently produce oval-shaped patterns by combining the atomizing air and fan air pressures. To the contrary, rotary bell atomizers produce circular-shaped spray patterns by applying air to shaping air rings, which consist of a set of holes positioned at defined locations behind the spinning bell-shaped disk. In some cases, these air streams not only shape the patterns but can also supplement the atomization process.

How each type applicator atomizes paint is worthy of consideration. Rotary bell atomizers break up the paint into droplets by applying centrifugal forces at the edge of the spinning disks, while conventional air guns atomize fluid by air impingement at the nozzle air caps. One major difference is that rotary bell atomizers have enough energy to produce a smaller-sized array of paint particles, with a higher percentage of the particles more uniformly distributed throughout. This changes the wet solids in paint film and can add to the overall smoothness of the surface finish.

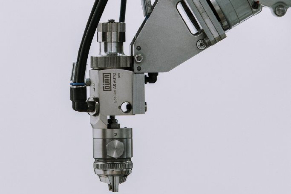

Rotary bell atomizers are more robust and precise than conventional air spray guns, and typically carry a higher investment. Decades of extensive R&D has been devoted to designing rotary bell applicators that meet harsh demands for the automobile industry. For instance, they must operate automatically, reliably and trouble-free for extended run times without manual cleaning. At the same time, they must produce very consistent coating thicknesses, with minimal defects, and the highest possible transfer efficiency. To the contrary, low-pressure air spray guns are streamlined and performance capabilities have limitations.

Rotary bell applicators are designed exclusively for automation. They offer some unique functionalities not possible with air guns, such as automatic spray head rinsing and integrated fluid return dump valves. Some can include internal fluid valves for internal 2K mixing of plural components inside the atomizer or for internal color changing. With automatic spray head cleaning, they can be more sustainable for continuous operation, allowing for reduced manual cleaning and maintenance.

Another difference is that air spray guns rely on cleanliness of the air cap orifices and overall condition to ensure a repeatable and consistent painting result. Sometimes a bad air cap can create unwanted splits and paint slug type defects. Rotary bells commonly produce a more repeatable finishing process.

There are considerable differences in how air spray guns and rotary atomizers function and are used on robots.

Typically, paint coatings used in the general industry are formulated for use by manual hand-held air atomizers. Automatic versions of the same applicator are used for automated processes. To use the same coatings with rotary bells, viscosity or reducing solvent changes might need to be adjusted to produce optimal or improved painting results.

Applicator type has a big influence on robot path programming. Air guns require that manipulators manage wrist positioning very specifically to keep the oval-shaped paint spray patterns orientated specifically on the workpiece. In contrast, the symmetrical plume produced by rotary bells allows robots more freedom of movement, enables shorter cycle times and greatly simplifies robot motion programs and paths, which helps avoid singularity issues. Based on the applicator, overall size, weight and angle as mounted on the robot can make programming easy or difficult. Overall, air guns tend to be smaller and lighter weight.

Rotary bell atomizers are used almost exclusively in the automotive industry.

Experience from the auto industry has proven rotary bells can offer considerable advantages based on paint savings, reduced cycle time, maintainability, paint re-work and booth cleaning. In circumstances when paints have very high cost or the quality standards require a smooth appearance, rotary bells might be the better choice. Clearcoat finishes are more appealing when applied by rotary bells due to an increase of evaporated solvents, which enhances material flow properties and helps prevent unwanted solvent pop defects. Depending on your paint process and targets for your automatic spray process, air guns can be the best overall choice.

In summary, both types of applicators have specific pros and cons. Air guns, particularly HVLP type applicators, are considered benchmark atomizers for low-pressure painting in the general industry. Rotary bell atomizers can offer significant key improvements for robotic painting. In the end, both atomizer technologies should be openly and carefully considered for your specific robotic spray process.

RELATED CONTENT

-

Deoxidizing Aluminum as a Pretreatment

This important first step can help prepare the metal for subsequent surface finishing.

-

Choosing and Troubleshooting Copper Electroplating Processes

Learn more on this inexpensive and highly efficient process.

-

Coating Systems with the Best Long-Term Performance

The best protection against corrosion and UV exposure, says Axalta’s Mike Withers, is electrocoat and a super durable powder coating.