DuBois Chemicals Launches PACRE Paint Pretreatment

Company says PACRE has flexibility to manage wide variety of metals and parts, and improve line density.

#curing

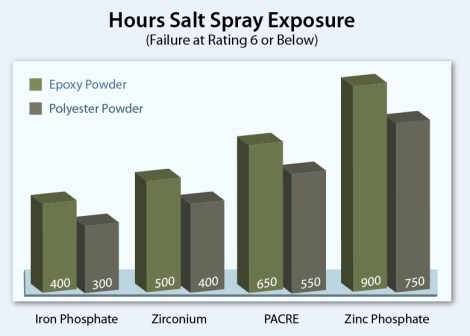

DuBois Chemicals has launched patent pending PACRE, a non-toxic, organic, micro paint pretreatment.

Featured Content

The company says that PACRE has the flexibility to manage a wide variety of metals and parts, and improve line density by expanding the capability of existing paint pretreatment equipment.

"This innovative polymer technology addresses difficult to finish edges and weld areas by pickling and treating in one step," said Bruce Dunham, Technical & Marketing Lead at DuBois Chemicals. "PACRE improves finish performance by removing laser scale, addressing weld burn and carbon smut on inconsistent steel while eliminating costly buffing and grinding steps. PACRE is a sustainable phosphate-free and heavy metal free alternative to traditional pretreatment processes that contain phosphates and consume energy for heat."

A before (left) and after (right) photo of smut removal.

Founded in 1920, DuBois manufactures specialty chemical solutions. DuBois has substantially increased its position in metal working fluids and surface treatment recently through the acquisition of Perkins Products, Galaxy Associates, Angler Industries and American Finishing Resources.

DuBois specializes in the areas of metal finishing/paint pretreatment, metalworking/lubricants, water/wastewater treatment, maintenance/equipment cleaning, paper chemicals, food processing cleaning/sanitizing, and transportation cleaning.

For more information, please visit duboischemicals.com

RELATED CONTENT

-

Are TGIC-Free Powder Coatings Right For You?

This alternative to TGIC-based polyester powder coatings offers similar performance and enhanced transfer efficiencies.

-

Preparation for Electroplating

What you should know about cleaning and electrocleaning.

-

Cleaning Prior to PVD/CVD Coating

Determining the cleanliness and chemical de-coating of PVD/CVD layers.