2020 Bright Design Challenge Concludes Virtually

The Metal Finishing Association of California has completed the 10th year of the Bright Design Program with the Pasadena College of Design, this year conducting the final presentations online to allow for social distancing during the coronavirus crisis.

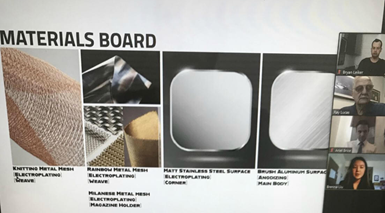

Due to the COVID-19 pandemic, this year’s presentations for the MFACA Bright Design Challenge were conducted via Zoom. Source | MFACA

The 2020 Bright Design Challenge final presentations were held May 1. Sponsored by the Metal Finishing Association of California (MFACA) and the National Association for Surface Finishing (NASF), the annual program prompts students to think beyond traditional design theory to develop next-generation creative and engineering solutions utilizing surface technology.

This is the tenth year of the program, which is coordinated with the Pasadena College of Design. Participants work within strict, realistic guidelines and focus on specific elements unique to the projects they are developing. Time-management skills play a strong role in the competition due to tight deadlines throughout the intense 12 -week competition. 12 students completed the class this year to work on marketable projects that incorporate surface finishing.

While in past years students spend time working in the metal finishing shops, because of the COVID-19 pandemic, this year’s class was hosted online.

12 students completed the class this year to work on marketable projects that incorporate surface finishing. Source | MFACA

“It was a great success considering we have never done it online,” says MFACA executive director Bryan Leiker. “This year the class was completed successfully online through Zoom to allow for social distancing. In past years the students have spent many days inside shops.”

$20,000 in scholarships were awarded to the students. This year’s winners were:

- Sunny Chen, First Place

- Brenna Liu, Second Place

- Jun-Yi Li, Third Place

Leiker adds, “All projects did a great job of incorporating surface finishing. Thank you to NASF for their continued support of this program. We look forward to another great class next year.”

RELATED CONTENT

-

Masking for Surface Finishing

Masking is employed in most any metal finishing operation where only a specifically defined area of the surface of a part must be exposed to a process. Conversely, masking may be employed on a surface where treatment is either not required or must be avoided. This article covers the many aspects of masking for metal finishing, including applications, methods and the various types of masking employed.

-

Sizing Heating and Cooling Coils

Why is it important for you to know this?

-

Blackening of Ferrous Metals

The reasons for installing an in-house cold blackening system are many and varied.