Advances in Near Neutral pH Descaling

Atotech’s UniPrep AC products offer versatile alternatives to conventional chemical and mechanical descaling methods.

Edited by Scott Francis

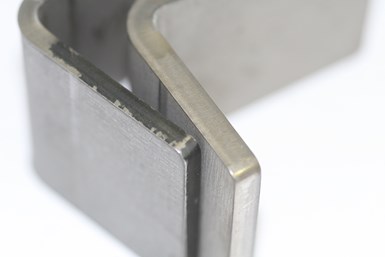

UniPrep AC successfully removes weld and laser scale from metal substrates creating a clean surface for the application of e-coat, wet paint and powder paint.

Photo Credit: Atotech

Consumer expectations for longer warranties have driven manufacturers to improve their processes in areas that have traditionally been ignored. For painted components, these neglected areas are often the welds and laser cut edges. The demand for longer-lasting products is requiring improvements in both paint coverage and corrosion resistance.

Removing oxide scale from welds and laser cut areas is important to improving the overall performance of a painted part, as the scale inhibits paint from adhering properly to a metal surface. When corrosion or delamination of the paint occurs on welds or laser cuts, it reduces the lifetime of the component. For industries like automotive, power sports, and construction and agriculture, reduced component life is a risk that manufacturers cannot afford.

Conventional scale removal applications such as grinding, media-blasting or strong acids are still widely used but have several drawbacks. Both mechanical and conventional chemical descaling processes pose severe health and safety risks.

Mechanical descaling is labor-intensive, generates dust and debris in the manufacturing area that creates a potential contamination source for the paint applications, and may create line-of-sight issues for recessed areas or complex part geometries. Poor paint adhesion can occur in heat-affected zones, on the reverse side of weld areas, which may not be accessible to mechanical descaling.

In addition to their inherent health, safety and environmental (HSE) concerns, strong acid pickles often have a very high etch rate on ferrous substrates, which results in a rapid increase in bath iron, contributing to a shortened solution life — ultimately leading to a greater burden on wastewater treatment operations.

Neither of these conventional descaling solutions is truly cost-effective.

Complete removal of oxide scale with UniPrep AC preparing the surface for subsequent paint application.

Photo Credit: Atotech

Atotech (Rock Hill, S.C.) developed its UniPrep AC series to operate at a mild, near neutral pH, without alkylphenol ethoxylates (APEs) and hard chelating agents, further reducing the burden for wastewater treatment operations and creating a safer work environment for manufacturing employees.

Brian List, Global Product Director, Paint Support Technologies (PST) from Atotech, describes UniPrep AC as “a turnkey pretreatment solution for applicators conducting welding and laser cutting activities.”

“UniPrep AC is the safest and most economical method for laser and weld scale removal and supports improved overall paint and part quality,” he adds.

According to Atotech, the UniPrep AC series provides applicators with solutions to safely, effectively and affordably improve the quality of their finished parts and to meet the demand for longer-lasting, higher-performing products.

Atotech North America| 800-752-8464 | atotech.com

RELATED CONTENT

-

The Hull Cell: Key to Better Electroplating - Part II

How to use it for planning, preventive maintenance and troubleshooting.

-

Top Reasons to Switch to a Better Cleaning Fluid

Venesia Hurtubise from MicroCare says switching to the new modern cleaning fluids will have a positive impact on your cleaning process.

-

Cleaning Limescale from Galvanized Steel

How do you clean white lime scale and rust spots on galvanize?