Soluble Salt Tester Measures Concentration on Metal Surfaces

The Positector SST Soluble Salt Tester from Paul N. Gardner USA is said to be durable, accurate and versatile.

#measurement-testing

Edited by

Photo Credit: Paul N. Gardner Co.

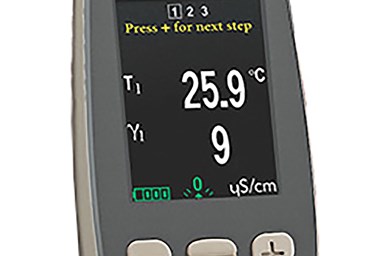

The Positector SST Soluble Salt Tester from Paul N. Gardner USA measures the concentration of soluble salts, or salt contamination, on metal surfaces in accordance with ISO 8502-6 and ISO 8502-9. The gage also features an onscreen interface that guides users through the Bresle test method.

The automatic storage of a background (blank) measurement is useful when performing multiple tests. The unit displays test duration, sample temperature, conductivity (µS/cm) and surface density (mg/m2 or µg/cm2).

The company says the gage is durable, accurate and versatile. The Positector SST is solvent, acid, oil, water and dust resistant, coming with a shock-absorbing protective rubber holster with belt clip. Additionally, the company offers a two-year warranty on the gage body and probe. The gage comes with a long form certificate of calibration showing traceability to NIST and a certified conductivity standard (calibration solution) to verify probe accuracy with a certificate also included. The Positector SST features automatic temperature normalization and sample temperature reporting, and conforms to national and international standards, including ISO, NACE, SSPC, IMO and U.S. Navy.

In addition, the Positector body accepts all Positector SST, 6000 III, 200, RTR, SPG, DPM, SHD and UTG probes, converting from a soluble salt tester to a coating thickness gage, surface profile gage, dew point meter, shore hardness durometer or ultrasonic wall thickness gage.

RELATED CONTENT

-

Viscometer Line Offers Measurement, Repeatability, Reporting

The Byko-visc RT Rotational Viscometer from Gardco provides detailed results analysis and review.

-

Pencil Hardness Test Kit Determines Relative Hardness

The Positest PT Pencil Hardness Test Kit is usable in both laboratory and field settings.

-

Brighton Science Unveils Cloud-based Surface Intelligence Platform

Next-generation solution uses data and analytics to prevent bonding and adhesion issues.