Investigation of Tin Whisker Formation

Immersion tin and lead-free hot air solder leveling (HASL) coatings based on SnCu or SnAgCu alloys are widely used as surface finish materials for printed circuit boards (PCB). These coatings prevent the underlying copper from corrosion and preserve its solderability during lead-free assembly processes and for a long storage life of PCBs.

#research #electronics #pollution control

Get Your Free Research and White Papers!

PFOnline.com expands technology zone with White Paper and Research ... with no silly fees.

#research #pollution control

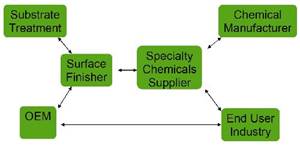

Impact of REACH Regulation on the Global Finishing Market

This paper is a peer-reviewed and edited version of a presentation delivered at NASF SUR/FIN 2012 in Las Vegas, Nev., on June 12, 2012.

#nasf #research #pollution control

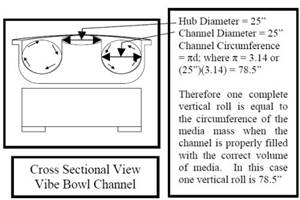

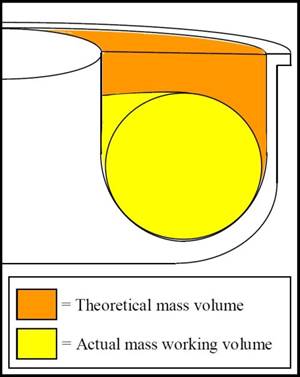

Considerations Regarding the Proper Loading of Vibratory Finishing Bowls for Optimal Quality, Performance and Throughput Efficiency

Available since the late 1950s, traditional vibratory bowl processing has advanced in recent years from being a generic deburring tool to being able to achieve high-quality, isotropic superfinishes on critical, dimensionally-challenged workpieces. This paper is a peer-reviewed and edited version of a presentation delivered at NASF SUR/FIN 2013 in Rosemont, Ill., on June 11, 2013.

#nasf #surfin #research

Latest Developments in Mass Finishing

New materials, manufacturing processes, automation and the need for better surface finishes have driven new developments in mass finishing. This article discusses finishing solutions for very large and heavy parts, explains drag finishing technology, introduces surf finishing technology and showcases two new media developments.

#research #surfin

Calculating Applied Media Force During Vibratory Finishing

What appear to be identically set-up vibratory bowls will finish identical loads of parts in varying time cycles. This paper offers a new technique to better predict what the operator will produce, by measuring the force applied to the parts. It is the efficiency of that force which controls the efficiency and speed of the refinement cycle.

#surfin #research

.jpg;maxWidth=300;quality=70)

.jpg;maxWidth=300;quality=70)