An Interview with Jim Jones, DIFCO

Jim Jones, consultant and former vice president of DIFCO, discusses his experience in the surface finishing industry.

#surfin

Edited by Scott Francis

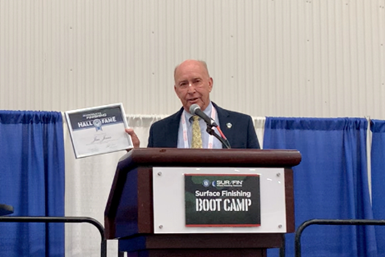

Jim Jones receives Finishing Hall of Fame recognition at SUR/FIN 2021.

Photo Credit: Products Finishing

Jim Jones has spent almost his entire life in and around the finishing industry. Jones’ father began working in the plating industry during WWII where he worked for Air Service Command in the plating shop at Warner Robins Air Force Base, and then working at Simmons Plating Works (Atlanta, Ga.) and eventually co-founding DIFCO. Following in his dad’s footsteps, Jones held summer jobs at finishing shops before enlisting in the military himself. After serving in the U.S. Air Force, Jones returned to DIFCO where he eventually became vice president and continues to consult to this day. Jones, a recent inductee into Products Finishing’s Hall of Fame, took some time to tell PF about his experience in the industry and offer advice for future stewards of finishing.

Tell us about your start in the plating industry.

Featured Content

I started in 1956 or 57 — one of my first summer jobs was working at Simmons [Simmons Plating Works, Atlanta, Ga.] on some of the process lines. I worked on cyanide copper baths, copper-nickel chrome baths, and did bright dip of copper using sulfuric acid and nitric acid. I worked there for a couple of years.

In 1960, Dad and a couple of other fellows started Dixie Industrial Finishing Company (DIFCO). Our first production was March 1960. I started to work at DIFCO in June of 1960 — about two weeks after I graduated high school. I worked on production lines, swept floors, cleaned bathrooms, and did pick-up and delivery. In September of 1960, I started at Georgia State University as a freshman. I’d go to school in the morning and then I would work at DIFCO in the afternoons.

That went on until 1961 when I made a decision to go into the Air Force. I wanted to get into the latest technology at that time, and that was intercontinental ballistic missiles. I started off on the Atlas missile program, then the Minuteman missile program.

Fast forward then into late 1964. My dad called me and said, “What are you planning on doing?” I was trying to decide whether or not to pursue a military career. When my dad said he needed me, then that answered the question. In March of 1965, I joined DIFCO full time.

So, I was raised in the business with my dad. During that time — from the late 40s to the 60s — I saw a lot of growth and a lot of changes within the industry.

How has the industry has changed?

I’ve seen the evolution of improving workplace safety through the 60s and 70s with the Clean Water Act, Clean Air Act, and then OSHA. There were a lot of regulatory issues that certainly came about that changed the industry.

There were those that were committed to the industry — that wanted to stay in the industry — that worked and complied. Over the years there were also shops out there that tried to stay under the radar and not worry about compliance with regulations. Those have disappeared, for the most part.

So, I’ve seen a great change in workforce safety and environmental improvement.

Another shift is in management. The philosophy used to be “produce all you can and try to watch your cost.” But, there wasn’t necessarily any real measurement for each process line to determine the actual operating cost. The focus was more on the costs to operate the shop versus the costs to operate a particular process line and what the throughput was.

Over the years, I’ve seen a huge change in measuring results. At DIFCO, the philosophy is “if you can’t measure it, you can’t manage it.” We went through an evolution of measuring and managing for success.

You’ve been a big cheerleader for this industry throughout your career. What are your thoughts on the importance of advocacy work?

I’ve worked in the business for a long time. I think you also have to work on your business — promoting your business and also promoting your industry.

In the metal finishing industry, unless you are an in-house shop that is part of an organization that manufactures parts, your job is to go out and find the opportunity to make other people’s parts look better, work better or last longer. So, be proud of who you are. Be proud of the service you offer and the value that you’re bringing to the manufacturing sector — and promote it.

When I look at the major OEMs that we’ve dealt with over the years from the aircraft industry to the automotive sector, from heavy equipment and construction equipment to nuts, bolts, screws, washers and fasteners — you can walk down the street or into stores and say, “Our industry is part of that. We bring value to it.”

What advice do you have for a new generation of workers as they grow into leadership roles in the finishing industry?

If you really love what you’re doing and love your business, you’re going to be innovative, you’re going to be creative, you’re going to surround yourself with talented people. One person does not have all the answers. All of us are better than one of us. A team of good, smart, energetic, passionate, dedicated people can overcome an awful lot of obstacles.

Sometimes you don’t know what the technology is that’s going to help you continue to improve, but you keep working and searching to try to find ways to improve, whether it’s reducing your rejects, increasing your throughput, reducing your overall cost, or improving quality — all of these things are part of continuous improvement.

In some areas, we’re going to see more automation coming around in the finishing industry — robotics in handling parts. The plating industry itself is also challenged with alternative finishes and alternative products that can affect the plating industry and electroplaters. So that’s another challenge that you have to look at. What other added value can you bring that’s going to help bolster your sales and your processes? Look at the handling that you have with some of the products that you’re processing and what is the added value you can bring to it?

You were inducted into Products Finishing’s Hall of Fame in 2019 and were recently recognized at SUR/FIN for your contributions to the industry. I was inspired by your humility when you accepted the award. Can you share your thoughts about a life’s work?

You don’t do it for recognition. I got involved with NAMF (National Association of Metal Finishers) and NASF (National Association for Surface Finishing) because I am passionate about the business and the industry and what we represent.

The number one thing is to like what you do. It’s better to take a lower paying job doing something that you really enjoy. If you chase the money, I don’t think you’re ever going to be happy. But if you have a passion for the industry, you’ll do a good job, it will be recognized and you’ll be rewarded.

Listen to the complete interview with Jim Jones in an episode of our On the Line podcast. Visit short.pfonline.com/OTL16.

RELATED CONTENT

-

A Process for Alkaline Non-cyanide Silver Plating for Direct Plating on Copper, Copper Alloys and Nickel Without a Silver Strike Bath

Traditionally, silver is electroplated in toxic, cyanide-based chemistry. Due to cyanide’s extreme hazard to human health and environments, developing non-cyanide silver chemistry is essential for the silver electroplating industry. Discussed here is an aqueous, alkaline non-cyanide silver plating technology, which can be directly plated over nickel as well as copper and its alloys. The silver deposits have perfect white color and better anti-tarnishing properties than other non-cyanide silver processes. The silver is plated entirely from the dissolving silver anode and the bath is very stable, and maintains a stable pH level both during plating and idle time. This new non-cyanide silver technology will plate bright silver that is perfectly suitable for electronic, industrial and decorative applications. .

-

Electroplated Tin-Nickel Coatings as a Replacement for Nickel to Eliminate Nickel Dermatitis

This paper is a peer-reviewed and edited version of a paper delivered at NASF SUR/FIN 2013 in Rosemont, Ill., on June 12, 2013.

-

Defects in Hard Chromium Deposits Part I: Causes and Cures

The causes of and remedies for defects in hard chromium deposits are explored in the first of this two-part P&SF article from 1984. Photomicrographs and SEM (scanning electron microscope) photographs will illustrate that most defects in various hard chromium deposits arise from defects in the basis metal. These defects may be in the original metal surface or may be caused by preplate finishing. Homogeneous hard chromium deposits can be produced only by eliminating these defects. Practical suggestions and procedures will be given.