The market share of automotive aluminum brake components and the quality requirements for their related elements are increasing. Factors such as corrosion protection, essential for the reliability of the brake system, and their decorative properties are critical for short and long-term viability.

Aluminum alloys now account for a large share of brake component materials, and anodizing such material places special demands on the coater and on the process suppliers. Let’s take a look at the requirements and specifications for anodized aluminum brake calipers used in the automotive industry, taking into account the relevant processes and aluminum alloys.

Featured Content

The Market

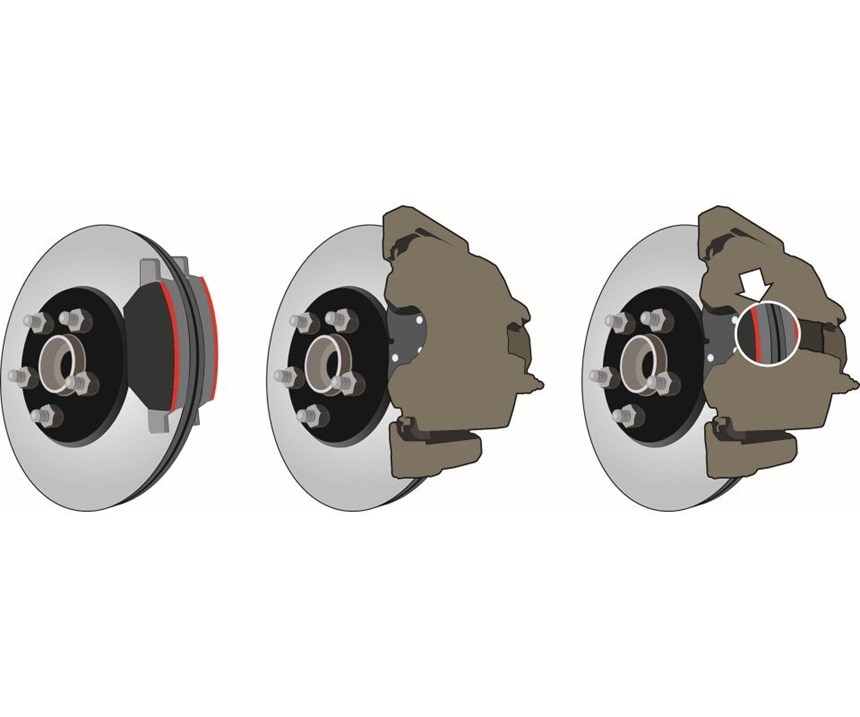

Modern braking systems in cars typically are made of cast iron or a combination of a cast iron bracket with an aluminum brake caliper housing. To achieve the same strength as comparable cast iron calipers, aluminum calipers usually have larger dimensions, although they nevertheless provide a comparative weight reduction. Due to space limitations and the lower forces involved, aluminum brake calipers in small and mid-size vehicles typically only are used on the rear axle. In larger vehicles, there is enough available space that they can be fitted on the front axle as well.

More than 92 million passenger cars were produced in 2016, and about 80 percent of them are outfitted with disc brakes. Of these, about 20 percent (15 million cars) are entirely or partially fitted with aluminum brake components, such as the brake caliper housing. To protect cast iron brakes against corrosion and to improve their visual appearance, these caliper housings are usually finished with a galvanic coating such as zinc or zinc nickel, and/or paint. Aluminum brake caliper housings for mass-production cars, which usually do not have any special corrosion requirements, are supplied without surface treatment or only with passivation. For higher-quality vehicles, the brake calipers can be anodized. This additional treatment increases the corrosion protection, wear resistance and improves appearance. Furthermore, for decorative purposes, the anodized surfaces can be colored during the anodizing process or painted afterwards. The VDA 237-300 standard on surface protection for brake calipers is the basis for many specifications.

Requirements

The type of protection and the corresponding treatment required depends on the type of application. A distinction is made between non-treated, painted, normal-anodized and hard-anodized surfaces. For these applications, aluminum alloys with a total maximum alloy content of 10 percent and a maximum copper content of 2 percent (maximum 5 percent for hard-anodized surfaces) typically are used. Alloys such as AlSi7Mg and AlSi5Cu4 have proved to be particularly well-suited for use in brake parts.

The requirements for each of these types of surface treatments are:

Non-treated surfaces: Aluminum calipers with minimal corrosion or aesthetic requirements are not usually surface-treated after casting and machining.

Painted surfaces: Painting of brake caliper housings is not only done for decorative reasons but also for long-term corrosion protection. Paint often is applied on the brake saddle surface in the direct field of vision. Such parts first are pretreated with hexavalent-chromium-free passivation, painted, then machined and anodized. The brake caliper housing surfaces need to have a uniform color and structure similar to the surfaces of corresponding parts, such as the brake caliper carrier. These parts have the same functional requirements as comparable unpainted calipers.

Anodized surfaces: For anodized surfaces, the requirement for oxide layer thickness is usually 5-25 microns (0.6-1 mil). To meet these tight tolerances, the part design must take into account that the anodizing process removes material. Such requirements do not always apply to the entire part, but are often restricted to major surface areas.

Related requirements and standards for anodized surfaces include:

- Appearance and color (consistent)

- Oxide layer thickness (UNI EN ISO 2360 or UNI EN ISO 1463)

- Dimensions/tolerance (drawing-specific)

- Roughness (drawing-specific)

- Corrosion resistance (UNI EN ISO 9227 or ASTM B117)

- Functionality (company-specific)

- Light fastness (ISO 2135)

- Resistance to liquids (gasoline, cleaning agents, UNI EN ISO 2812-1) most often used for painted surfaces

- Resistant to high-pressure cleaning (company-specific) most often used for

- painted surfaces

Depending on the application, a normal-anodized coating typically is used for brake caliper housings and hard anodizing for pistons or other components that require a high degree of abrasion resistance and moderate corrosion resistance.

Anodizing can be supplied as colorless, or the anodic film can be colored. The coloring is accomplished by dyeing the oxide layer with organic dyestuff. The final stage in the anodizing process is sealing by means of hot water, nickel or chromium salts. In some specifications, applying a friction modifier like polytetrafluoroethylene (PTFE) is required. The minimum requirement is that the surface be both smooth and free of stains after anodizing.

High corrosion-protection requirements dictate that an oxide layer thickness of 15-25 microns (0.6-1 mil), up to 30 microns (1.2 mil) in the case of hard anodizing, be applied for automotive brake calipers or components. The thickness measurement should be performed on machined surfaces to ensure sufficient accuracy. The eddy current method in accordance with UNI EN ISO 2360 or the microscopic method according to UNI EN ISO 1463 are recommended.

Corrosion resistance is determined by a neutral salt spray test (NSS) according to UNI EN ISO 9227 or ASTM B117. The requirements for corrosion resistance in the NSS are dependent on the thickness and type of sealing, but are generally between 120 hours and 480 hours at less than 1 percent white rust. A corrosion resistance requirement as demanding as 720 hours at less than 5 percent white corrosion could also be requested.

Evaluation of sealing quality also must be conducted at least 48 hours after anodizing. The test method commonly used is a color drop test with previous acid etching according to ISO 2143:2010 (maximum rating of 1).

The average hardness of hard-anodized layers is about 400 HV. If aluminum alloys with more than 1 percent copper are being used, the average hardness of the coating will be a little less, at around 300 HV.

The Anodizing Process

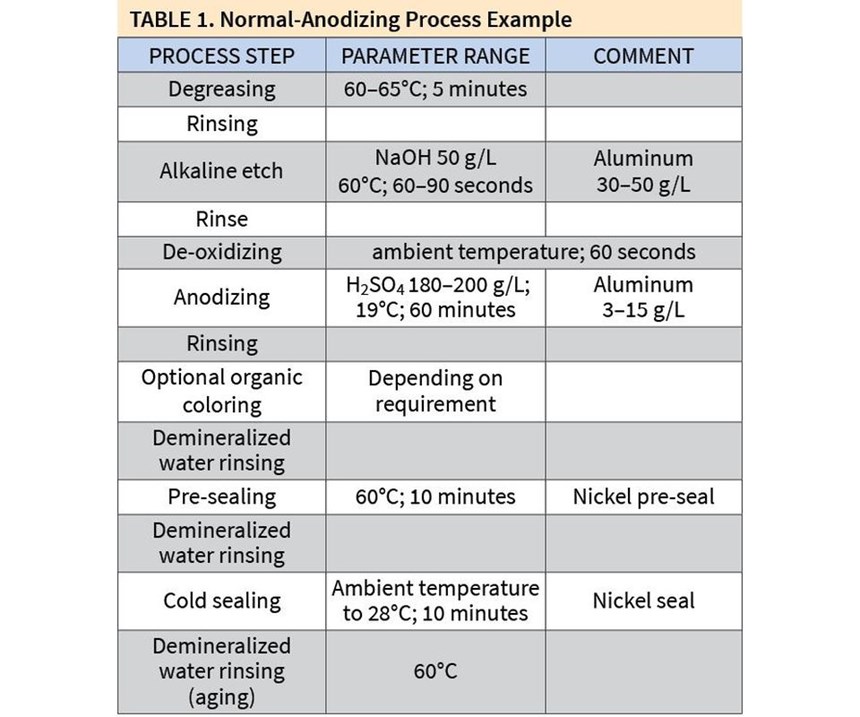

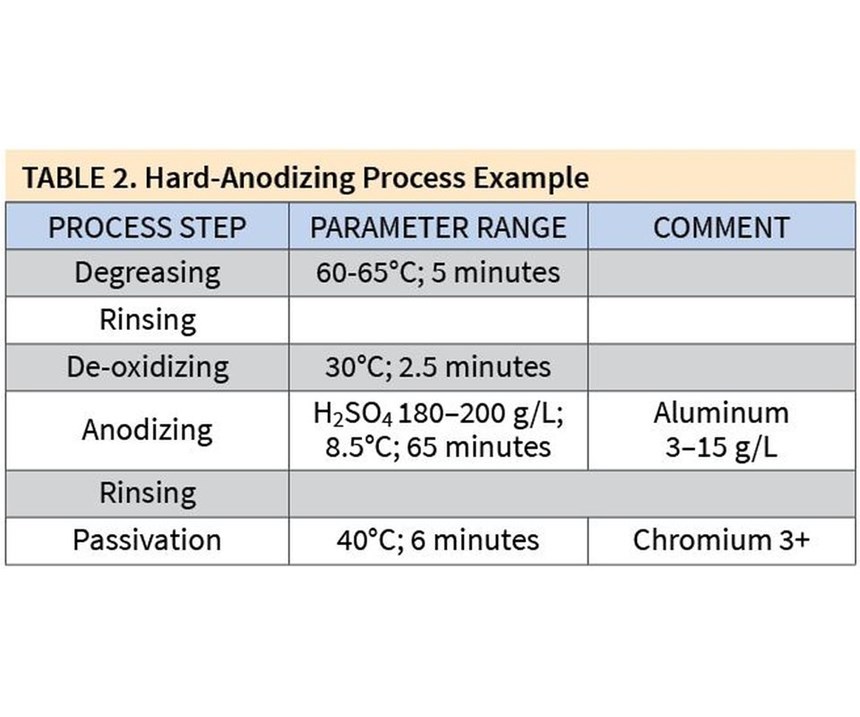

Meeting the requirements described here for anodizing automotive brake calipers follows the general parameters outlined in Tables 1 and 2.

As a pretreatment prior to anodizing, the brake calipers must be degreased, deoxidized and sometimes brightened. Depending on the customer’s request, the parts may also first be grit-blasted, mechanically ground or polished. Electrolytic polishing baths in particular can be used for small parts to increase the uniformity of the oxide layer and to improve their appearance.

Anodic-generated oxide layers with corrosion protection properties require sealing. This can be a hydrothermal seal using demineralized water at temperatures of at least 96°C for a period of three minutes per micron layer thickness. Alternatively, a combination of presealing at at least 60°C followed by a cold seal can be implemented. The combination of nickel-containing seals with a subsequent hot-water seal is the most common procedure. Depending on the specification, a chemical trivalent-chromium-based seal (with or without subsequent hot sealing) may also be used.

The example in Table 1 covers the normal anodizing of brake housings to a thickness of 20 microns (0.8 mil), followed by cold sealing to achieve a high corrosion protection of 480 hours NSS on AlSi7Mg.

The example in Table 2 covers hard anodizing of brake housings to a thickness of 25 microns (1 mil), with subsequent passivation to provide high corrosion protection and achieve 120 hours at less than 1 percent white rust and 720 hours at less than 5 percent white rust in NSS on AlSi7Mg.

Future Market Trends

Due to increasing requirements related to the environmental impact of chemical products and safety, the current demand is for nickel-free sealing processes that work at low temperatures while meeting the increased standards for corrosion protection and appearance. Leading system suppliers have already invested resources in the development of such methods, however the processes currently available still do not meet all the market demands.

Another trend is the desire to unify the appearance of parts installed on a braking system. The visual appearance of acidic zinc-nickel-coated cast iron holders and anodized aluminum brake calipers are intrinsically different, and the market still has not found a universally acceptable solution for this.

The high demands on aluminum automotive brake components make anodizing the finishing process of choice, but it is coating applicators and process suppliers still must work together to successfully develop optimal processes to meet the complex OEM requirements.

About the Author

Stefan Lenzer is director of metallurgy at MacDermid Enthone, based in Forst, Germany. This article was presented at the 2017 Aluminum Anodizers Council conference.

RELATED CONTENT

-

Plating Q&A: Can you color stainless steel?

Our expert, Art Kushner, says yes, you can color stainless steel, but it is not a process that is typically performed in a plating shop. Read more about his answer.

-

Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.

-

Anodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.