Chevy Sonic Gets Eco-Friendly Paint Job

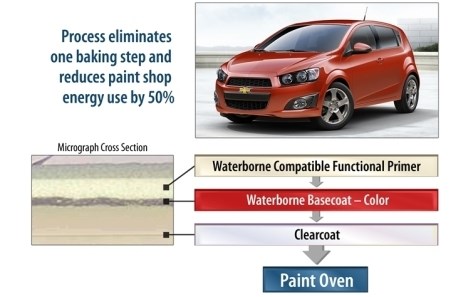

Thanks to this system, as well as other recent shop enhancements designed to minimize energy use and paint-solvent emissions, Orion Assembly’s paint facility will reduce greenhouse gas emissions by approximately 80,000 metric tons each year at full production, cut solvent emissions by about 108,000 lbs. annually, slice $40 of manufacturing costs from each vehicle and use 50 percent less process energy per vehicle—all while being heated by natural and landfill gas instead of more emissions-intensive coal-fired boilers.

#workforce development #energy #pollution control

RELATED CONTENT

-

Filter Press Troubleshooting and Optimization

Zachary Beckman of Haviland Enterprises Inc. discusses proper filter press maintenance for optimization of wastewater treatment systems.

-

Plating Q&A: Can you color stainless steel?

Our expert, Art Kushner, says yes, you can color stainless steel, but it is not a process that is typically performed in a plating shop. Read more about his answer.

-

NOx Scrubbing Technology Breakthrough

This paper presents research findings and practical results that address the treatment of the problematic greenhouse gases nitrogen oxides (NOx) and sulfur dioxide (SO2).