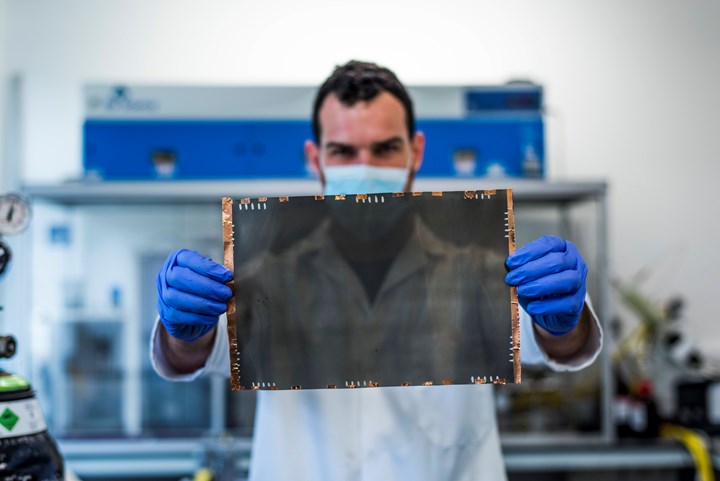

A technician at Advanced Material Development Ltd. (AMD) examines the integrity of a just-sprayed EMI shielding on a sheet of polymer film.

Photo Credit: All images Advanced Material Development Ltd.

It’s long been established that nanoparticles in fractions of a percent to a few percent can have outsized impact on the performance of a base material, adding enhanced functionality like thermal and/or electrical conductivity, oxygen barrier properties, and other features. While nanoadditives have been used in plastics and films for decades, a growing area of work is in functional coatings that do more than extend durability and improve aesthetics, but actually increase commercial viability. It should be noted that manufacturing control of particle size and distribution, as well as the engineering of dispersion are all important factors for achieving the best results for industrial applications.

A company active in this area is Advanced Material Development Ltd. (AMD, Guildford, U.K.), which works collaboratively with university post-doctoral teams and commercial partners to develop, test, scale up, and license commercial applications in 2D nanomaterials. These typically are provided in liquid form factors — primarily waterborne, although solvent-based formulations are available — including additives, sprayable coatings, and flexible or stretchable films for segments like advanced sensors, electronic devices, and composites. Two important areas of work involve modifying thermal or electrical conductivity.

Featured Content

Dissipating Heat

As electronic circuits have gotten exponentially faster and more powerful, the amount of heat they generate during operation has also increased. To eliminate metallic shielding and make normally thermally insulating materials like plastics/composites be thermally (but not electrically) conductive, AMD has built a series of technologies around hexagonal boron nitride (h-BN), a refractory compound of boron and nitrogen resistant to heat, pressure, and chemicals. h-BN’s crystalline isostructure is analogous to another common nanoparticle, graphene nanoplatelet (GNP), and is already used as a lubricant for paints, cosmetics, pencil graphite, and in cement for many dental appliances.

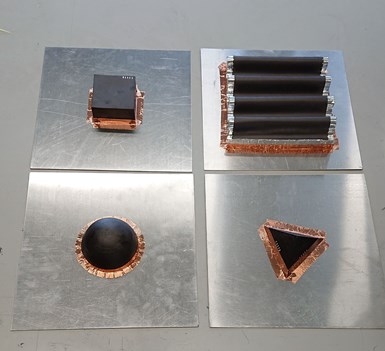

AMD has developed both EMI/RFI shielding coatings as well as thermally (but not electrically) conductive coatings. Protecting delicate power electronics from excessive heat buildup and from electrical “noise” are important uses for these materials.

Based on its work in motorsports, automotive, and aerospace, AMD has developed three different approaches for bleeding heat away from sensitive devices in challenging environments where thermal performance and part mass and cost all are important considerations. Thermal pads for direct heat management are one solution. The pads may be a rigid or elastomeric polymer with an adhesive on one side and a coating of h-BN on the other. The thin pads are adhered to the surface of a component, part, or enclosure and then physically connected to a heat sink via a non-electrically conductive interface. Since heat tends to travel the path of least resistance, like electrons, excess heat is pulled away from a power electronics source via the thermally conductive h-BN and transferred to the heat sink where it is bled off without risk of unintended electrical connection (i.e., shorts).

Coatings (water-based inks with sustainable binders) are another thermal management technology in AMD’s toolbox. They are typically used to extract heat from enclosed environments (e.g., inverter enclosures or battery covers protecting electric vehicle (EV) battery packs) in situations where designers must balance thermal conductivity against part weight and cost. For example, polymer composites are replacing steel and aluminum in EV battery covers. However, composites tend to be thermally as well as electrically insulating, so design teams must be prepared to address both electromagnetic interference (EMI) shielding and thermal management. The current standard is to place an aluminum heat shield around the battery enclosure, which adds cost, requires space, and increases the mass of battery systems. However, AMD's solution is to combine the effects of electrically conductive nanocarbons and thermally conductive h-BN into a coating system that delivers both electrical and thermal conductivity. This approach effectively replaces the conductive properties of aluminum heat shields and/or aluminum or steel enclosures while keeping cost, mass, and packaging space at a minimum without sacrificing battery pack safety or performance.

In cases where thermal management is needed but coatings are not suitable — as where watertightness, high scratch resistance, or even elastomeric properties are needed, as when sensors or devices are mounted directly to the suspension or drivetrain — the nano-additive can be incorporated into a rigid or elastomeric polymer base material. While h-BN embedded in a non-thermally conductive polymer will not be as thermally conductive as a coating of pristine nanoparticle, formulation work can, to an extent, help mitigate this issue, the company says.

“Increasing the loading of the nanomaterials is not necessarily better, as early adopters of graphene in reinforced composites found out,” explains Tom Barlow, AMD manager of business development. “Add too little nanomaterial and the effects of the increased interfacial stress transfer provides insufficient benefit. However, add too much and agglomeration can occur, weakening the structure. It’s the same with our thermal management nano-formulations. Engineering the combined material for optimum performance is critical for success.”

Electrical Shielding

AMD focuses on 2D nano-based materials in liquid form factors. Here, a technician is applying a sprayable EMI shield, which can be applied with a variety of standard equipment and dried at room temperature or via infrared heat.

Another focus at AMD is electrical shielding — specifically from EMI and radio frequency interference (RFI) — using combinations of high aspect ratio nanocarbons. Much of this work has emerged from developments for automotive and aerospace to address sources of electrical “noise.” In automotive, key sources of such emissions come from drivetrain electronics as well as advanced driver assistance systems (ADAS), which use combinations of radar and LiDAR to help prevent collisions. Shielding sensitive electronic systems from electrical noise to stop damage and/or malfunction is increasingly important with EVs as overall drivetrain voltages increase and as power switching technologies based on gallium nitride rather than silicon are used to handle more power and switch more rapidly, generating ever more damaging emissions.

“ESD [electrostatic dissipative] shielding requires less conductivity and can be done quite cost effectively,” explains Paul Mumford, AMD director of business development. “However, if you look at the EMI and RFI frequency ranges we’re dealing with for power electronics in next-generation EVs, plus ADAS and 5G systems — electronics switching has become so much faster and it generates so much more noise that we now have to protect sensitive equipment from frequencies ranging from hundreds of kilohertz to multiple gigahertz. Interestingly, while aluminum has long been used for electrical as well as thermal shielding, it’s most effective at higher electrical frequencies. For the lower end of the spectrum, such as the frequencies emitted by inverters, additional shielding can sometimes be required. It’s difficult to cover the full range of frequencies at the same time in the same location, so we’ve developed two different formulations that can be applied if needed.”

Mumford explains that regardless of whether the inverters used are standalone units or are incorporated directly into other core EV components, such as transmissions and differentials, AMD has a nanomaterial shielding option that will work — either as a supplementary capability to address an otherwise difficult-to-manage frequency range or as a lightweight coating on the inside of composite enclosures.

“The tunable nature of these nanomaterials lets us target particular frequencies, enabling us to develop a solution that blocks one frequency range entirely but not another, such as shielding against power-electronics frequencies while permitting much higher frequency ADAS sensor communications to pass through,” Mumford adds. “The thickness of these coatings can vary from a few microns — to attenuate frequencies <20 decibels — to 50 or 100 microns — where 99.99% attenuation of 40- 50 decibel EMI frequencies is required.” He adds that AMD works closely with customers to develop the lightest, highest performance, most cost-effective solution possible that will address their thermal and/or electrical conductivity needs. Automotive applications are expected to be commercialized by the end of 2023, with motorsport applications commercializing sooner.

RELATED CONTENT

-

Nanotechnology Start-up Develops Gold Plating Replacement

Ag-Nano System LLC introduces a new method of electroplating based on golden silver nanoparticles aimed at replacing gold plating used in electrical circuits.

-

VDA 19 and its Impact on European Manufacturing and Cleaning

The German Association of the Automotive Industry’s VDA Volume 19 is the first comprehensive standardization document for characterizing the cleanliness of products within the automotive industry’s quality chain.

-

Evolving Automation in Automotive

A look at the latest liquid coating technologies for the automotive sector from leading robotics and surface finishing technology providers