Is a Cold Seal Right for Your Anodizing Operation?

Exploring the advantages, challenges and best practices of cold seal processes.

Cold seal bath in operation.

Photo Credit: All photos courtesy of Reliant Aluminum Products LLC

A cold seal, also known as a room-temperature seal, is a sealing bath that contains nickel and fluoride and is used at ambient temperatures. Best results are obtained with temperature regulation, which ensures a more consistent rate of sealing reaction. Recommended sealing temperatures for Clariant cold seal products are between 80° and 90°F (27° to 32°C).

The sealing mechanism of a cold seal is different from a hot water, hot nickel or mid-temperature seal in that it is an impregnation process. Nickel and fluoride are impregnated into the pore structure by reacting with the aluminum anodic oxide (AAO). The resulting nickel-aluminum-fluoride compounds further react with water to swell the pore walls to complete the sealing reaction.1

Featured Content

The seal process can be performed as a stand-alone, single-stage sealing process or as a duplex stage sealing process. The single-stage process requires seal times of approximately 10 minutes for coatings less than 0.5 mils in thickness and 15 minutes for coatings greater than 0.5 mils in thickness. A single-stage process has the disadvantage of requiring a minimum 24-hour cure period before seal quality testing (i.e. modified dye stain or acid dissolution test) can be performed. The duplex stage process involves a shorter cold seal time of five minutes for coatings less than 0.5 mils in thickness and eight minutes for coatings greater than 0.5 mils. The second stage is usually hot DI water between 160° and 180°F for five minutes. The second stage increases the rate of reaction of the nickel-aluminum-fluoride compounds with water, curing the seal at a much faster rate. Seal quality tests using this method can be performed proximate to sealing. For greater corrosion resistance and lightfastness, the second stage can be substituted with a hotter DI water bath or even a mid-temperature nickel seal.

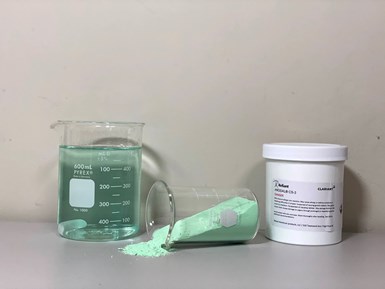

Anodal CS-3 powder product and seal bath

Clariant cold seal products come in two forms: powder (Anodal CS-2N and Anodal CS-3) and liquid (Anodal CS-2 Liquid). Each form has advantages and disadvantages. The liquid products are generally the most economic form. In addition, material handling is easy, as the product can be pumped into a feed tank or directly into the process bath. The primary disadvantage of the liquid form is the pH of the product. In order to make the product drum stable, a very low pH is necessary. Therefore, addition of the product to the production bath causes a decrease in the bath’s pH. If too much product is added, the pH may fall outside of operating parameters, negatively impacting the sealing reaction. Comparatively, powder products generally do not affect the pH when added to a production bath. However, material handling can be more difficult because the powder must be carried and added to the tank by hand.

Anodal CS-2 liquid (right) and seal bath (left)

Control of a cold seal bath is achieved by monitoring time, temperature, nickel content, pH and fluoride content. Nickel content is monitored through titrating with EDTA. A combination pH and ion meter is used to monitor pH and fluoride content. All five of these parameters must be within recommended ranges for the seal to adequately perform.

Dye contaminated seal bath (right) and after carbon filtration (left).

Despite potential significant advantages, there are some potential disadvantages to a cold seal. For example, anodize operations engaging in organic dyeing will experience high rates of dye bleed in the seal. Good dyeing practices may help to mitigate this problem. Operations that need to pass various crazing (cracking of the AAO film due to thermal expansion) standards such as AAMA 611 may have some difficulties using a cold seal. Cold sealed AAO films can craze at temperatures as low as 140°F. Another potential drawback is that seal performance of a cold seal bath requires all five parameters to be well controlled. The necessity for added equipment in the form of an ion meter and ion probes is often seen as an obstacle to the use of cold seals.

Despite these potential disadvantages, the ability to mitigate them, coupled with the benefits of cold seal, should give rise to the consideration of using a cold seal. For example, if your operation engages in organic dyeing, a cold seal can be filtered with carbon to remove dye contaminating the seal from dye bleed. Sufficient filtration allows clear and dyed articles to be sealed in the same bath. Filtration of dye also enhances bath life over other seal technologies. In addition, some dyes exhibit increased lightfastness when properly sealed in a cold seal bath.

Another advantage is that cold sealed AAO films have excellent alkaline corrosion. Evidence supporting this can be found when previously anodized and cold sealed parts need to be stripped and reworked. These parts must first be soaked in an acid bath before caustic removal of the anodized finish. If this step is not taken, the part can take significant time to strip and may result in unevenly stripped parts.

Yet another advantage is that cold seal baths are generally less affected by contamination than other seal technologies, resulting in longer bath lives. This, in conjunction with lower operating temperatures, carbon filtration and fewer bath makeups reduces utility and waste treatment costs.

All three Clariant cold seal offerings are ROHS compliant. Anodal CS-3 and Anodal CS-2 Liquid are REACH compliant. Anodal CS-2N is not REACH compliant, as it uses a metal salt to reduce the green hue a cold seal can sometimes impart. All three products are MIL A8625 compliant.

I am often asked what the “best” seal is. Unfortunately, there is not one “best” seal. Seal choice is dependent upon the situation with each of the seal technologies excelling in certain circumstances. If plant floor space was unlimited and tanks were free, I would want each of the various seal types on my ideal line. However, given the constraints of the real world, I would suggest strong consideration of using a cold seal.

1Brace, Arthur W., The Technology of Anodizing Aluminum, 3rd edition, Interall Srl, 2000

About the Author

Kevin Janis

Kevin Janis is the business development manager for Reliant Aluminum Products. He received his Bachelor of Science degree from the University of Wisconsin-Madison where he majored in chemistry and philosophy. He also received his Juris Doctor from the University of Wisconsin-Madison School of Law. Kevin has been involved in aluminum finishing for 21 years. He first became involved with aluminum finishing as an assistant research chemist at UOP developing novel coatings on aluminum. He became involved with anodizing at Linetec where he served as the anodizing technical manager. After leaving Linetec, he consulted to Clariant serving as the marketing manager and technical services manager of the aluminum finishing business segment for all of Asia. He has been the technical sales and service agent for the upper Midwest for Clariant products for the past 16 years. Throughout his career, he has been involved with continuous improvement efforts including Six Sigma and lean manufacturing.

RELATED CONTENT

-

Plating Q&A: Can you color stainless steel?

Our expert, Art Kushner, says yes, you can color stainless steel, but it is not a process that is typically performed in a plating shop. Read more about his answer.

-

Test Methods For Evaluating Anodized Aluminum

Benefits of anodizing include durability, color stability, ease of maintenance, aesthetics, cost of initial finish and the fact that it is a safe and healthy process. Maximizing these benefits to produce a high–performance aluminum finish can be accomplished by incorporating test procedures in the manufacturing process.

-

Aluminum Anodizing

Types of anodizing, processes, equipment selection and tank construction.