Share

“Colors are forces, radiant energies that affect us positively or negatively, whether we are aware of it or not.” — Johannes Itten

The automotive market has come a long way since the days when customers could have “any color so long as it is black.” Today, the color spectrum has expanded in all aspects of vehicle production.

Specifically, in the case of brake components, the growth and profitability of the aftermarket in the past 10 years have accelerated the use of colors. This has caused the worlds of color and corrosion to collide in both OEM and aftermarket to meet the growing demands.

With product lines ranging from pretreatment to topcoats, Atotech has a proven system that provides high corrosion protection, excellent paint adhesion and consistent quality at a competitive cost. Since the system is available in production, OEMs and tiers can utilize it for current and future programs.

Market Challenge

For more than a decade, various attempts have been made to apply paint over zinc-nickel plating on calipers with varying and often dismal results.

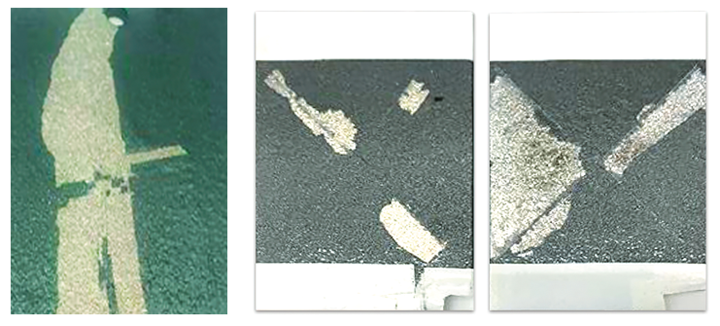

Zinc-nickel + paint adhesion failures (Photo Credit: All images courtesy of Atotech)

Poor paint adhesion can result from limited resources available within individual organizations and the slow and cumbersome process that results from involving many suppliers. Typically, tiers and applicators rely on knowledge from external sources. As a result, the primary means to develop a process is trial and error with innumerable variables. Even after positive laboratory trial results, scaling to production has been difficult. Magnifying the problem, each OEM specification has a unique set of test methods and attributes that must be verified. Due to this, even when a solution is found for one OEM it may not translate to others. Suppliers of everything from e-coat, powder coat, liquid paints and electroplated corrosion-resistant finishes have struggled to integrate zinc-nickel and an organic topcoat. This is no longer true.

To understand the magnitude of the challenges that exist, the following is a review of the various aspects of the process and how they contribute to accomplishing the intended goal.

Pretreatment

Myriad soils exist in the marketplace that pretreatment needs to address. Brake components (calipers, housings, etc.) are predominantly made of cast iron with some machined surfaces. Due to the process involved there is a propensity for oils and machining additives to become trapped in the pores of the material. Additionally, depending on storage conditions, there may be other contaminants or flash rust present on the part surface that is difficult to remove with the conventional cleaning process.

Knowing what contaminants exist and having products that properly address each is the first step to developing a robust cleaning process. The next step includes having the proper analytical tools to identify if a surface is clean prior to plating. The process doesn’t end there — the final step is to ensure quality is maintained through the life of a program. This last step is achieved by leveraging analytical methods for cleanliness and scientific data to know when cleaners are due for replacement before they have a detrimental impact on production.

Plating

Not all zinc or zinc-nickel products are created equal. Electrolyte type, distribution, efficiency, cost, and corrosion performance are the major attributes to consider when deciding on which product and process to use. When viewed through the lens of paint adhesion, plating distribution from the High Current Density (HCD) to the Low Current Density (LCD) areas is one of the most important things to consider.

Acid electrolytes are the dominant process used for brake components. Although acid electrolytes provide a superior plating speed compared to alkaline, they are notorious for providing a disparity in thickness distribution. Typically, the HCD to LCD thickness ratio is 5:1, but it can exceed 10:1 depending on the chemistry and process used.

Paint adhesion is affected by the adhesion of the plating to the substrate (cleanliness) and the thickness in various HCD and LCD areas. Excellent thickness distribution limits the plating thickness in the HCD areas while still achieving the minimum thickness requirements in the LCD areas. This ratio, when correctly proportioned, results in excellent paint adhesion and corrosion performance.

Post-Treatment

The number and types of post-treatment passivates available in the marketplace are overwhelming. The passivation step is often the final layer that is presented to the paint application and accentuates the previous processes. The passivate interacts with both the underlying electroplated finish and the organic coating applied over it.

Balancing corrosion performance with paint adhesion is a challenge, with many being forced to choose one or the other. Thick-film passivates provide maximum corrosion protection, but frequently this thickness negatively impacts the ability of the paint to adhere. Conversely, thin-film passivates have superior paint adhesion, but the degree of corrosion protection can be compromised.

Consequently, choosing the correct passivate is paramount for the success of the coating stack.

Organic Finishes

The final steps include an organic finish, or the application of paint.

Paint types and application methods can vary and include powder coating, e-coat and liquid paint. Each coating method has its own unique set of challenges, which must be critically considered because they will influence the outcome. Powder coating is typically the most affordable process, but it is limited in the variety of colors and gloss levels that are available. Liquid paints can be matched to body colors, but typically require more controls in the application process. Selection of the organic topcoat depends on the goals for the application, including a variety of performance characteristics.

Another step related to the organic topcoat is determining the proper material handling in moving the parts to the organic finish line. It is incumbent upon the supplier(s) to select a process that maintains the integrity of the underlying electroplated/passivated finish. This pretreatment step is critical in removing any handling/storage/movement soils, while maintaining the integrity of the surface coating.

A new level of corrosion protection

Atotech’s Corrosion Protection 3.0 (CP3.0) approach streamlines the supply chain and results in better quality finishes at a significantly lower cost compared to conventional approaches.

Atotech has a rich history supplying cleaners, zinc and zinc-nickel electrolytes, high-performance passivates and, the most recent addition to its product portfolio, powder coating products. The company’s zinc-nickel + paint system provides OEMs and tiers the confidence that their parts will meet the highest quality standard when specified on new programs.

Using Atotech’s TechCenter and applicators committed to bringing the best technology to the market, Atotech has successfully met the requirements of major automotive OEMs by applying powder coat, e-coat and liquid paint over Zinni 220, the company’s latest acid zinc-nickel technology that provides the speed of acid zinc-nickel with a distribution ratio (hcd to lcd) similar to alkaline zinc-nickel. In addition to the thorough cleaning process, the consistent thickness of the zinc-nickel film results in superior adhesion.

Since the entire process is controlled by Atotech, there is a full understanding of all of the materials and processes used, with no ownership issues.

Prior to being offered to customers, each system has undergone extensive lab and production scale tests. In order to support PPAPs and new model launches, a PFMEA is available to assist technicians that are available to advise Atotech’s applicators and customers (OEMs, tiers, etc.) about how each product should be used. This support is available in the primary manufacturing countries globally, so programs can easily expand to different regions as business expands.

Throughout the research and development process, Atotech’s focus complete synergy between the electrolytes and passivates. The selection of an environmentally friendly passivate used for this system further highlights the company’s commitment to the environment and pioneering new performance expectations.

Ultimately, Atotech’s systems include powder coating, liquid paint and e-coat which are available to meet a variety of requirements.

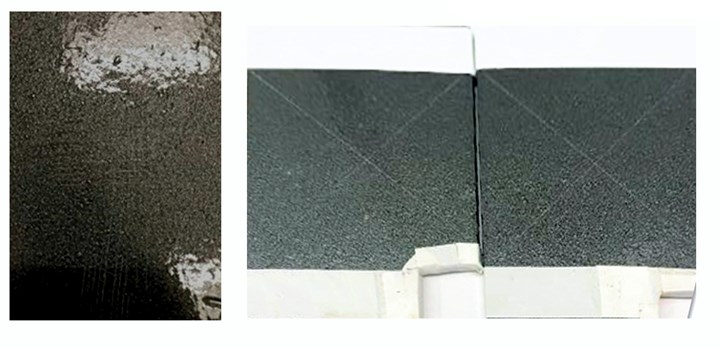

Atotech’s process showing improved adhesion

Organic coatings over Atotech’s zinc-nickel process: (clockwise) Liquid paint; powder coat; E-coat / KTL over Atotech’s zinc-nickel process; and Atotech system after 70 cycles of GMW 14872 (bottom left)

Conclusion

There are hundreds of potential combinations of products and variables that must be considered when developing new multilayer coating systems. Each layer stack combination needs to be understood for a successful application. Atotech supplies cleaners/pretreatment, zinc and zinc alloys, and organic surface treatments. such as phosphates and phosphate alternatives, zinc flake and powder coat products, and uses this expertise to create synergistic systems that provide improved corrosion protection, aesthetics and durability.

Based on field experience, Atotech’s CP3.0 approach has provided OEMs and tiers a way to expedite commercialization of new finishes, and it includes virtually limitless possibilities of combinations that can be considered. The market has responded well to Atotech having a library of tested systems to review and the ability to critically examine each step in the finishing process will continue to shorten the development cycle for the supply chain. Full line supply provides increased confidence that the entire value stream will supply industry-leading products and meet current and future demands.

Visit atotech.com

About the Author

Andrew Pfeifer

Andrew is the business manager, corrosion protection North America for Atotech USA LLC.

Related Content

TTX’s Automated Conveyor Carrier System Offers Wireless, Flexible Operation

ACC system designed for reliable, consistent point-to-point movement of everything from small to heavy parts.

Read MoreCoatings Plant Evolves with Market Trends

Expanding its focus from exclusively serving the RV industry, one of this company’s stand-alone coatings plant has successfully extended its services to additional markets.

Read MoreChemical Removal Advantages for Paint Application Lines

The removal of cured paint from fixtures — hooks, racks, grids or carriers — plays a bigger role than many realize in maintaining consistent coating quality and line efficiency.

Read MoreWeathering the Storm

This is a story of how one industrial coatings company kept the lights on in the wake of hurricane devastation.

Read MoreRead Next

The Best Tape for High-Temperature Applications

High-temperature tapes are designed with maximum heat ratings indicating the highest temperature they can withstand for a very short time.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreReducing Material Use and Overspray

Looking for applicators or process improvements for reducing material use and overspray? Binks offers helpful advice for searching out new solutions.

Read More