Ultraviolet (UV) light has been used to cure coatings for more than 30 years, and companies have been successfully using UV-cured powder coatings for more than 20 years. UV-cured powder coatings can replace solvent liquid coating (in some cases thermoset powder coating) and are a finishing material of interest for many new materials and products.

High-power UV lamps are the source of curing-light energy, and arc (or medium-pressure lamps) dominate the market. Within the past five years, lamp manufacturers have developed and are producing UV light-emitting diode (LED) lamps with higher UV-energy output. These are replacing arc and medium-pressure lamps, with some specified for use in new finishing systems.

Featured Content

UV curing is very different from air dry or thermal (heat)-energy curing systems. It is important to understand cure and know how to evaluate it. Cure is a chemical reaction that takes place inside the coating and is measured by the number of crosslinked oligomer chains or fully reacted double bonds remaining in the coating matrix following exposure to the curing system. The types of curing systems are ambient or “air dry,” thermal-heat energy or UV-light exposure. Differential scanning calorimetry (DSC) is a reliable and repeatable method to measure a coating system cure. Users will often use a Methyl Ethyl Ketone (MEK) solvent test to evaluate cure. Research shows that this test can produce false negative and false positive results.

UV-curable liquids and powder coatings are photopolymerized materials with a chemical photoinitiator that instantly respond to UV-light energy, starting the reaction leading to cure. To cure a UV-powder coating, a separate melt stage precedes the cure stage, which typically takes 1-2 minutes or longer, depending on the substrate. UV curing is almost instantaneous. When considering UV-cured coatings for liquid or powder, it is necessary to balance the operating parameters of the coating system, process speed and the coating material with the spectral range of the UV bulb and lamp system energy output. If the bulb’s spectral output does not match the absorption range of the photoinitiator or if the lamp system is underpowered, the coating may not completely cure.

Regulatory and Environmental Constraints

Consumer interest in environmentally friendly materials (as well as health and safety regulations eliminating or reducing the amount of hazardous materials) are changing how coatings are made and how chemicals are used and applied. The user’s alternate choices are waterborne; no/low-solvent and UV-cured liquid coatings; and thermoset and UV-cured powder coatings.

Waterborne coating is the fasting growing sector of the coatings industry. Water is replacing solvents in paints and coatings. Besides being challenged to be a 1-to-1 quality and performance replacement for solvent coatings, waterborne coatings have economic, social and environmental costs that have yet to be fully measured. Water is a scarce and unequally distributed natural resource.

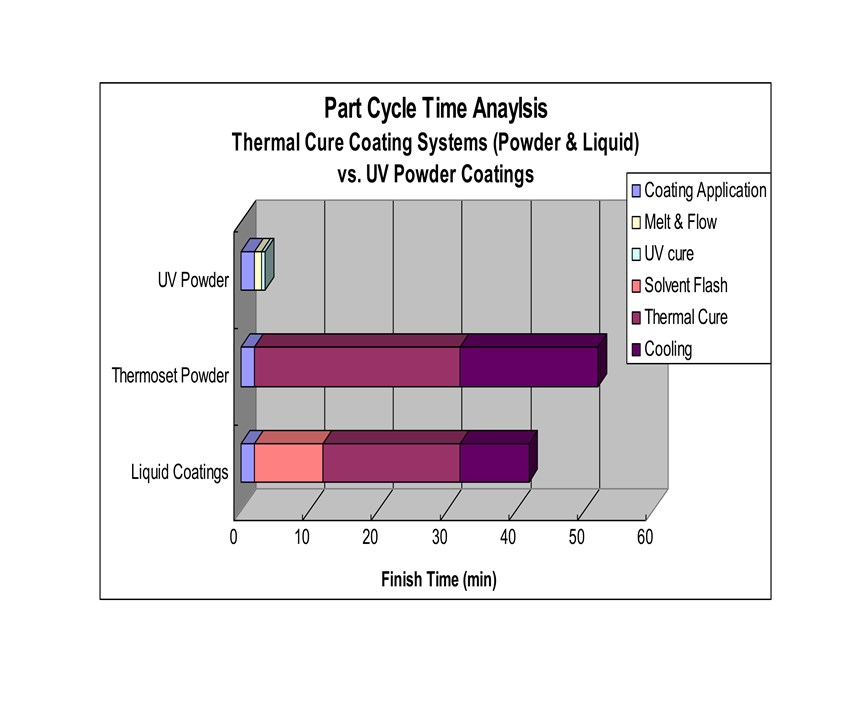

UV-cured powder coatings have many operational benefits—they lower energy consumption and the total application system has a smaller plant footprint, increases productivity, reduces material usage and produces higher profits per hour. In addition to these operational benefits, UV-cured powder coatings have health, safety and regulatory benefits. As they are 100 percent solid, they are solvent and water free. They don’t have hazardous or regulated chemicals and don’t require permits to make or use. When factored into a total applied cost model, these benefits make UV-cured powder coatings a sound investment. Graph 1 captures the productivity benefit of UV-cured powder coating compared to thermoset powder and liquid coatings. Each bar is the sum of time needed to complete application-to-cure.

UV-cured powder coatings and thermal powder coating are made the same. The difference is the UV resin, which is specifically designed to be cured with UV light. Typical resin types are polyesters, epoxies and urethanes. Additives and pigments (along with the photoinitiator) are added to the resin and complete the formulation. The unique difference between thermal and UV-cured powder coatings is the separation of a continuous heat-to-melt-and-cure phase into a short heating-to-melt phase and followed by a near instant UV-cure phase.

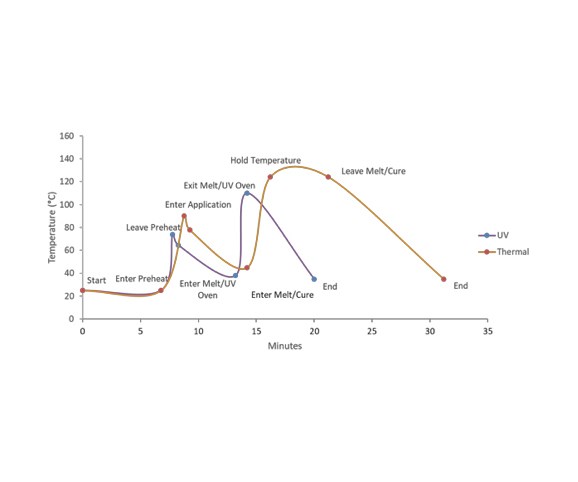

Figure 2 is an example of the time and temperature differences between an ultralow bake thermal (ULB) powder and UV-cured powder coating to finish medium-density fiberboard (MDF). The ULB powder has a 5-minute melt/cure time at 130oC, with a start-to-finish time of about 32 minutes. The UV-cured powder is in the oven for one minute heated to 110oC, followed by an almost instant UV cure. The total line time start-to-finish is 20 minutes.

UV-Light Curing Technology

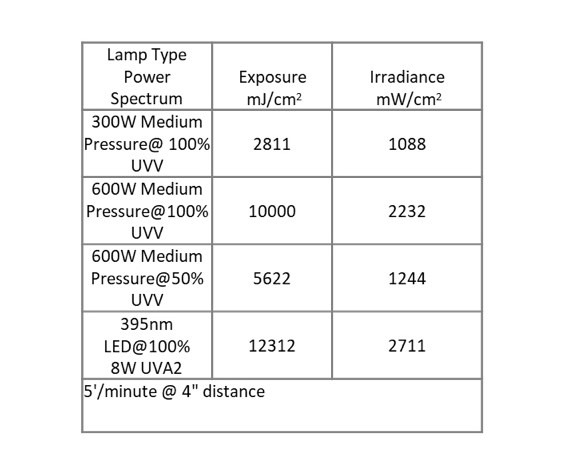

UV-lamp output is described as irradiance (intensity), and lamp power is measured at a specific distance, with the notation as mW/cm2. As distance changes, irradiance changes. The second descriptor is exposure (energy density), the amount of the lamp’s power reaching the surface of the object being cured as it moves through the lamp’s light field — the notation is mJ/cm2. As line speed varies, exposure changes. It is important to understand how curing conditions change as lamp power, distance and time change.

Table 2 shows the results from four measurements of three lamp types — 300-watt and 600-watt medium-pressure mercury lamps and a 395-LED, with power output at 50 percent and 100 percent. The third condition shows where the measurement on the UV spectrum was made (either UVV and UVA2). The two constants for all tests are a distance of 4 inches and a speed of 5 feet per minute.

UV-light spectrum has three bands between 100Nm to 400 Nm. Lamp manufacturers named a fourth band UVV 400-450 Nm. This band is important because UV energy in this range cures thick coatings such as UV-cured powder coatings. Arc and medium-pressure UV lamps broadcast light energy across all four UV bands and into visible light above 400 Nm. Depending upon the type of lamp, the energy irradiance and exposure will vary across the spectrum. Photoinitiators absorb UV light at different wavelengths. The UV light’s emission wavelengths must match the absorbing wavelengths of the photoinitiator to start and complete the cure response in the coating.

UV-LED Curing

Development and commercialization of UV-LEDs is a recent and important development in UV-light curing technology. UV arc and medium-pressure lamps are very effective, but have limitations. They are energy inefficient; the bulbs emit IR heat; over time lamp intensity degrades; they are doped (enhanced) with heavy metals to change the irradiance spectrum; and large arrays require a makeup air cooling system and are difficult to adjust or mount on a robot. UV LEDs address many of those limitations.

DSC testing shows that a 395 Nm UV LED will cure a clear, black, white and other nonconflicting UV-absorbing, pigmented, UV-cured powder coatings. LED manufacturers are increasing the power output (intensity) of UV-LED emitters, thus expanding application possibilities. It is possible to mount a UV-LED emitter on a robot to move the emitter to areas that otherwise could not be cured because UV curing is by line of sight. The surface of the object being cured must “see” the UV light. UV-LED curing is not without challenges. More research and development is needed to overcome UV-absorption conflicts in pigments and photoinitiators.

UV curing of coatings is a proven technology and offers significant operational, health, safety and regulatory benefits making UV curing a practical and profitable alternative to traditional curing. Ongoing developments in UV-LED technology are increasing the market for UV-cured materials, specifically UV-cured powder coatings. Improvements in UV-LED equipment and concurrent UV-cured powder coating chemistry developments have made the combination of UV-LED and UV-cured powder coatings an enabling finishing technology — not only for replacing solvent coatings, but also for many new materials and product markets.

Michael Knoblauch is president of Keyland Polymer Material Sciences. Visit keylandpolymer.com.

RELATED CONTENT

-

Is Your Electroplating Waste Hazardous?

Some that bears precious metals is, and there are a host of regulations to consider when recycling.

-

Drivers of Change

Is your metal finishing software ready for an upgrade?

-

Pretreatment for Painting

Better adhesion, enhanced corrosion and blister resistance, and reduced coating-part interactions make pretreatment a must.