Anoplate Welcomes STEM Students for Plant Tour

The students listened to the benefits that surface engineering can provide, took part in a hands-on demonstration and gained insight into the little known—and much less appreciated—technical vocational career opportunities in metal finishing.

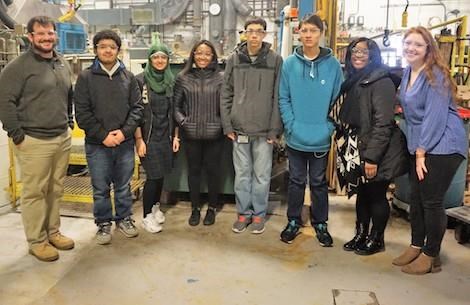

Students toured Anoplate's facility as part of a STEM program.

Anoplate Corporation of Syracuse, New York, recently participated in the inaugural STEM Job Shadow Day organized by the Manufacturers Association of Central New York.

Featured Content

Twelve high school students interested in science, technology, engineering and math from Nottingham High School toured Anoplate’s facility, which specializes in metal finishing services including plating of copper, nickel, chromium, zinc, silver, gold, cadmium and tin, various types of anodizing of light metals, conversion coatings such as passivating and phosphating, dry film lubrication, small lot painting and vacuum impregnation.

The students listened to the benefits that surface engineering can provide, took part in a hands-on demonstration and gained insight into the little known—and much less appreciated—technical vocational career opportunities in metal finishing.

Anoplate continually welcomes opportunities to promote career opportunities in the industry and STEM curriculums through local high schools and universities.

For information, visit anoplate.com.

RELATED CONTENT

-

Aluminum Anodizing

Types of anodizing, processes, equipment selection and tank construction.

-

Smut and Desmutting

Question: I am new to this industry and have heard about smut and desmutting operations.

-

Nickel Electroplating

Applications, plating solutions, brighteners, good operating practices and troubleshooting.