Brown and Caldwell Receives Funding for PFAS Incineration Study

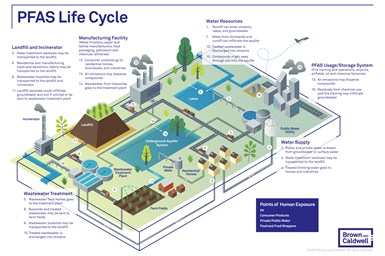

Firm partners with utilities and academia to analyze the environmental impacts of forever chemical incineration at wastewater facilities.

#regulation #sustainability

Edited by Scott Francis

Environmental engineering firm Brown and Caldwell (Walnut Creek, Calif.) has been granted funding from The Water Research Foundation (WRF) to study the fate of per- and polyfluoroalkyl substances (PFAS) through sewage sludge incineration.

Thermal treatment of PFAS-laden wastewater solids through sewage sludge incinerators (SSIs) offers a potential PFAS control strategy; however, with few published research studies available, the ability of SSIs to fully mineralize PFAS is unknown.

To this end, a research team led by co-principal investigators Lloyd Winchell (Brown and Caldwell) and Dr. Detlef Knappe (North Carolina State University) has been awarded a $100,000 grant from WRF through its Tailored Collaboration Program to support utility-specific/regional issues. The study aims to explain the fate of PFAS compounds through SSIs and provide utilities with an indication of the extent to which SSIs can eliminate or reduce PFAS emissions. The team includes chemists, PFAS specialists, and thermal processing experts from 10 utility partners and one trade organization. One supporting partner is the city of Cedar Rapids, Iowa, mindful of its role in understanding PFAS at its Water Pollution Control Facility.

“The city is excited to support this opportunity to further our commitment to environmental stewardship and the protection of human health,” says Cedar Rapids City Manager Jeff Pomeranz. “With this research in hand, we and other utilities can responsibly progress with facility designs that account for PFAS entering our systems.”

Aspects of the study include identifying municipal water resource recovery test sites with different technologies to combust solids captured from the treatment process. Once collected, samples will be analyzed, and a research report prepared to help utilities inform their assessment of appropriate PFAS handling strategies.

According to Brown and Caldwell, the study recently commenced and is scheduled for completion within 18 months. Collection and sample analyses are expected by the end of 2021. The report will be finalized within six months of receiving test data.

RELATED CONTENT

-

In Mechanical Finishing, All That Glistens Is … Or Is It?

Surface finish types for commercially supplied stainless steel sheet are detailed in various standards. ASTM A480-12 and EN10088-2 are two; BS 1449-2 (1983) is still available, although no longer active. These standards are very similar in that they define eight grades of surface finish for stainless steel. Grade 7 is “buff polished,” while the highest polish—the so-called mirror polish—is designated Grade 8

-

Is Your Electroplating Waste Hazardous?

Some that bears precious metals is, and there are a host of regulations to consider when recycling.

-

What Temperature Profiling System is Right for Me?

Today, profiling systems that are both sophisticated and easy to use can give a clear pass/fail finding, document regulatory compliance, let operators know when and where their ovens are trending out of acceptable limits or show that a process is within suppliers’ or customers’ specifications.