Less Maintenance Required for Pneumatic Vertical Piston Pumps

Dürr's newest generation of pneumatic vertical piston pumps are said to require less maintenance because of the air motor’s ability to operate without oil.

Edited by

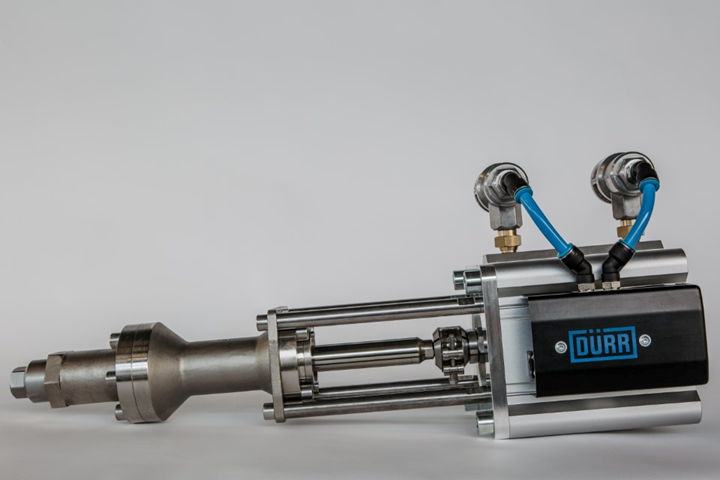

Dürr’s latest pump generation cuts maintenance times and increases process reliability. Photo Credit: Dürr

Dürr has developed a series of pneumatic vertical piston pumps that are said to increase process reliability and require less maintenance. The EcoPump2 VP is designed for various media typically found in industry and can be used in many fields, such as mechanical engineering, metalworking, woodworking or the furniture industry.

The company says the pump only needs one seal for most applications, which makes it quicker and easier to change than the previous model. The fluid parts can be disconnected from the air motor with conventional tools via a quick coupling. The air motor can operate without oil, reducing required maintenance compared to previous generations. Another benefit is that the contactless changeover valves used to regulate the air motor changeover promote a higher process reliability. Using quick-exhaust valves cuts changeover times, reduces pulsations and improves performance.

With five different versions of the EcoPump2 VP — covering a pressure range from 22 to 306 bar — the pump is suitable for applying paints, high-viscosity materials and adhesives to furniture, steel constructions and more. It can also handle acidic hardeners commonly used in the 2K process in the North American market without difficulty.

The company says initial feedback from customers has been consistently positive. Customer testimony notes the pump is quieter, pulsates less and takes less time to clean than the previous model.

RELATED CONTENT

-

Preventing Solvent Pop

Preventing solvent pop on an industrial paint line...

-

Coating Thickness Measurement: The Fundamentals

A review of available test methods, common applications and innovative instrumentation...

-

Combining AGVs, Software for Greater Paint Shop Efficiency

The EcoProFleet from Dürr is an automated guided vehicle that coordinates with the company's DXQ software to bring about maximized utilization.