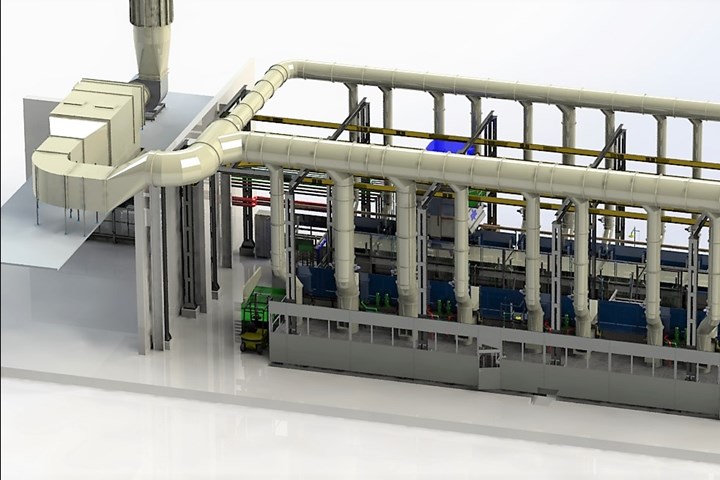

Turnkey Solutions for Surface Finishing, Metal Treatment

Photo Credit: Surface Finishing Engineering Ltd.

#surfin

Surface Finishing Engineering’s (SFE) exhibit will showcase the skills and capabilities the company has acquired from decades of industry knowledge, innovative technologies and intelligent design. SFE’s team will guide visitors through its approach to each client and each industry it works within. In addition, the booth will feature imagery, videography and testaments from clientele to demonstrate SFE’s standing in the surface engineering and metal treatment industries. A short presentation will display SFE’s offerings of all-encompassing, turnkey solutions for bespoke requirements from early discovery stages through to final commissioning.

Surface Finishing Engineering Ltd. | +44 1902 409186 | www.sfeuk.com | Booth 264

RELATED CONTENT

-

Electroless Nickel Coatings: Appearance, Gloss and Surface Morphology

For decorative coatings, appearance is the essential purpose for application, but also for functional surface finishes it becomes increasingly relevant as an added value on top of specified technical requirements. Appearance is affected by spectrum and intensity of incident light, roughness and morphology of the coating surface, optical properties of the coating material, eventual superficial oxide films, and individual perception. The predominant factor is surface roughness, which in turn depends on base material roughness, quality of substrate pretreatment, and nucleation and growth kinetics of the electroless nickel (EN) deposit. Interdependency of gloss measurements with roughness measurements and with chemical composition of coatings was investigated for new generation mid-P EN processes and compared to traditional ones.

-

Methods and Formulas to Determine Internal Deposit Stress in Applied Metallic Coatings

Internal stress exists in electroplated and chemically applied metallic coatings. This paper reviews the test procedures for measuring deposit stress and the formulas used to calculate stress values. Many formulas used require modification to obtain actual internal stress values. Errors in this regard are examined and common mistakes are explained.

-

Electroless Nickel-plated Steel versus Stainless Steel: Case Studies

This paper highlights two case studies of manufacturers that have replaced, or done studies to replace, stainless steel with electroless nickel-plated mild steel. In both cases, cost savings could be realized while maintaining or improving product quality.