CCAI Presents 'Maintaining a Quality Finish' Webinar Series

This three-part series will be presented by CCAI corporate members who have proficient knowledge and experience with each of the webinar topics.

#education #curing

Pretreatment Change Eases Wastewater Headaches

By: Hannah Coombs - Products Finishing

OMG Roofing Products gets help with wastewater treatment.

#pollution control

Eyelet Manufacturer Finds Safer Paint Stripping With Aquastrip

The manufacturer was buying a stripping product from another company, but there were several issues regarding service, value and performance. Not to mention the strong odor and no one really wanted to use it.

#pollution control

Hubbard-Hall's Chuck Kellogg Receives Industry Lifetime Achievement Award

Kellogg is the 5th person to receive the NACD Lifetime Achievement award in its 44 year history

#masking #pollution control

Hubbard-Hall's Molly Kellogg Leads "Women Leaders in Manufacturing" Event

"Rosie the Riveter in the 21st Century: Women Leaders in Manufacturing" led by Kellogg and Maureen Hanley-Bellitto, United Bank Senior Vice President.

The Importance of Rinsing in Metal Finishing Operations

The focus or driving force is to eliminate contaminants from the surface.

#basics

A Conversation with … Molly Kellogg, Hubbard-Hall

Hubbard-Hall promoted Molly Kellogg to President and CEO upon the retirement of Andrew Skipp; both are 6th generation family members of the company whose roots date to 1849

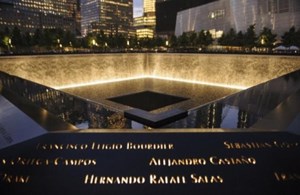

Hubbard-Hall And The Lasting Tribute At The Sept. 11 Memorial

Customer was tasked with providing a durable, corrosion resistant black finish to the panels and Hubbard-Hall’s Black-Magic product line was chosen

#pollution control #masking

Molly Kellogg Is New CEO At Hubbard-Hall

Kellogg, currently Executive Vice President, will become President and CEO upon the retirement of the current President and CEO, Andrew K. Skipp, on December 31

Drawn to Closed-Loop Cleaning

For Gem Manufacturing of Waterbury, Conn., meeting customer quality standards is critical to the success of the business. Part of that means removing the synthetic and water-soluble drawing lubricants used in Gem’s transfer and progressive presses, as well as any other contaminants that could have a detrimental impact on performance.