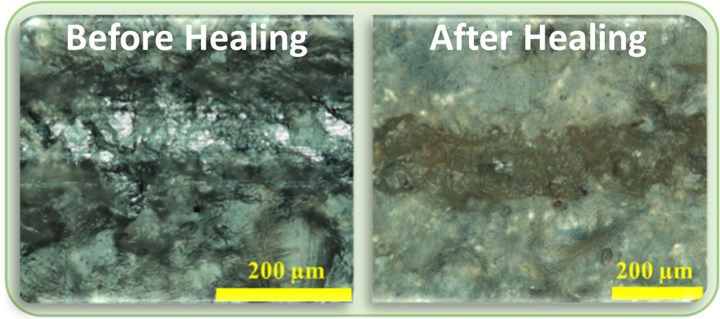

ATSP-based coatings exhibit self-healing properties upon exposure to localized heating. Above left, a section of ATSP coating has been scratched. Above right, after localized heating (270°C for one hour), the damaged area is completely healed.

Photo Credit: All images ATSP Innovations Inc.

Before he passed away at age 92 in 2021, Dr. James Economy of the University of Illinois at Urbana-Champaign invented at least 20 polymer technologies, authored more than 250 research papers and 47 book chapters, and was issued more than 100 U.S. patents. One of the polymer technologies he invented roughly 13 years ago is an aromatic thermosetting copolyester (ATSP) with numerous useful properties. The technology is owned by ATSP Innovations, Inc. (Houston, Texas) and is starting to be used in its first commercial applications. Two of the many interesting uses are as a corrosion-protection coating for metals and as a friction/wear-enhancement coating for polymer or metal bearings or an additive for other polymer wear coatings or bearings.

Versatile chemistry

As a vitrimer that cross-links like a thermoset but can be reprocessed like a thermoplastic, ATSP is an uncatalyzed, condensation cure polymer system containing both amorphous and liquid crystal segments. Once cross-linked, it offers excellent dimensional stability, broad chemical and oxidative resistance, and high thermal performance (glass-transition temperature (Tg)>250°C; it won’t thermally degrade below 500°C), making it ideal for use under challenging environmental conditions. It also provides good processability, is weldable, and can be reprocessed, enabling scrap and end-of-life parts to be recycled. Even its mechanical properties combine the best of thermosets (tensile modulus=4.2 gigapascals) and thermoplastics (8-10% strain to failure).

Featured Content

With a specific gravity of 1.32, ATSP is a good electrical insulator, exhibits very-low moisture uptake (0.2-0.3%), and has a long shelf life at room temperature without the need for refrigeration/freezing between uses. Reportedly, the polymer is low outgassing, VOC free, and is said to have no environmental/health/safety (EHS) concerns.

As an aromatic oligomer, it offers excellent wetout of fibers and fillers (including nanoparticles), making it useful as a composite matrix or as a synergistic additive to help other polymers bond with reinforcements/fillers. Prepolymers can be solvated and applied as coatings or powders can be produced for use as coatings or for impregnating other materials. Still another use is producing high-performance melt- or solvent-spun fibers. ATSP also can be used to produce an open-cell foam with excellent sound damping, thermal insulation, and high inherent flame retardancy (UL 94 V-0 listing at 1.5 millimeters; limiting oxygen index (LOI)=40%) with intumescent/char properties, making it useful as a barrier material. Still another use is as a reversible structural adhesive with high shear strength over a broad temperature range. It offers excellent adhesion to a broad range of materials — from polymers and composites to metals and glass — and it can be bonded/unbonded/rebonded multiple times without losing properties. On its own, the polymer offers extremely low wear, making it interesting for tribological applications. It also can be used as an additive to improve the wear resistance of other polymers, such as polytetrafluoroethylene (PTFE).

The polymer’s most unusual feature is a property called solid-state interchangeable/exchangeable bonds. A function of interchain transesterification reactions (ITR), this property enables previously cross-linked parts to be “welded” together through the Z axis (similar to blocking between layers of thermoplastic films) after application of pressure (~1.4 MPa) and heat (270-340°C). Parts can just as easily be separated by adding more heat and pulling. This feature also accounts for the polymer’s rebondable adhesive properties and its self-healing properties after localized heating in the damaged area, which is useful for extending the service life of coatings.

No Rust

ATSP-based coatings strongly adhere to metals whose melt temperatures exceed 270°C (including iron, steel, aluminum, titanium, bronze, brass, zinc, and copper) where they provide excellent corrosion protection, improved lubricity, and resist cracking in challenging environments, including extreme or cyclic temperatures, high oxygen, and immersion in seawater. The company reports its coatings have been tested for seven days in 80°C salt water (ASTM G85) and six months in room temperature salt water (ASTM G31) with no cracking or change. In other testing, coated products have been submerged in 1 molar sulfuric acid solution for 70 days and also in salt water with 12% mole hydrogen sulfide and balanced carbon dioxide gas at 80°C (NACE TM0177) with no change or sign of corrosion in either case. The polymer also can be used for galvanic isolation and as a polyimide thin-film replacement where high dielectric strength is required (as in high-voltage wire jacketing).

An interesting area of research has focused on coating inside and outside diameter (ID/OD) threaded connections on API E-grade steel pipes used in corrosive and abrasive down-hole drilling conditions in the oil and gas industry. The company says the polymer can easily be customized for application needs and coating technique.

Even a thin (50-micron) coating of ATSP on threaded pipe connections (e.g., API E grade steel above) has been shown to protect threads and seal interfaces against galling and abrasion, permitting multiple make up/break out uses without requiring reapplication.

No Wear

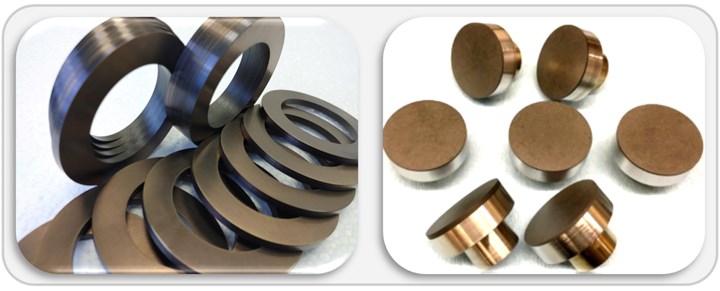

Another interesting ATSP use is as a thin coating on the wear surfaces of high-performance polymer and metallic bearings. In general, high-performance polymer bearings possess low surface energy, low shear strength, and low elastic modulus. Combined with low friction, this makes them useful for tribological applications. However, wear resistance can be degraded under extreme working conditions involving high loads, high speeds, and high temperatures. Application of a properly formulated ATSP coating, however, can increase wear resistance with minimum friction, such as on the wear surface of compressor bearings and thrust-pad bearings. The company reports wear improvements even under extreme temperatures — single or multiple cycles of -96°C to 300°C — as well as under changing lubrication conditions (i.e., boundary/starved and dry sliding). The coating has even been shown to improve performance of bearings in electric submersible pumps used in oil wells and drilling strings for oil and gas exploration where friction surfaces are required to endure high temperatures, high loads, high speeds, high pressures, and extremely abrasive and corrosive conditions.

The company cites a tribological study performed on its coating compared with PTFE alone (Teflon 958G-414 from The Chemours Co.) and a polyetheretherketone (PEEK)/PTFE blend (1704 from Southwest Impreglon Inc.) under a pin-on-disk experimental setup designed to simulate working conditions on a tilting-pad bearing in electric submersible pumps with starved lubrication conditions. Of the three coating materials, ATSP showed the lowest wear rate (4.15 x 10-8 cubic millimeters/newton-meter) after a sliding distance of 155.5 kilometers corresponding to over 1.08-million cycles. Pure PTFE was next in performance followed by the PEEK/PTFE blend. At a coating thickness of only 40 microns, the ATSP coated bearing ran a total sliding distance of 2,216 kilometers, which is equivalent to 15 miillion cycles — a value 13.4- and 24.8-times higher than the running life of the PTFE and PEEK/PTFE coatings, respectively.

Even at coating thicknesses of only 40 microns, ATSP has been shown to significantly improve wear performance of both polymer and metal bearings under challenging conditions.

Currently, ATSP Innovations supplies the polymer in several form factors: powdered resin, molding compounds, and bulk solids. Powdered resin formulated for corrosion protection or wear enhancement coatings, low friction/wear polymer bearings and as a wear-enhancement additive for other polymers is called NOWE, while powdered resin formulated for adhesive applications is called Self-Bond, and molding compounds are called Estherm.

“In both laboratory and field settings, our NOWE coatings have shown significant improvements in wear/friction properties for a variety of metallic and polymeric materials — often under extremely demanding conditions, such as swings from cryogenic to high temperatures, low to high loads and speeds, dry to lubricated interfaces, as well as exposure to dust and sand,” notes Kian Bashandeh, Ph.D., ATSP Innovations research scientist. “The polymer also has successfully demonstrated enhanced corrosion protection of metals during temperature cycling, under exposure to seawater, and in high oxygen environments. With several years of testing and formulation work now behind us, we’re looking forward to seeing the first commercial applications roll out with our development partners.”

About the Author

Peggy Malnati

Peggy Malnati regularly writes for PF sister publications CompositesWorld and MoldMaking Technology magazines. pmalnati@garpub.com

RELATED CONTENT

-

Unique Coating Reduces Friction of Sliding Ceramic, Metallic, and Polymer Components

An extremely thin, hard diamond-like carbon (DLC) coating decreases the coefficient of friction (COF) of components to nearly zero, while increasing wear resistance.

-

Shedding Light on Surface Inspection

State-of-the-art reflector-based lighting system improves luminosity and ergonomics for surface inspection tasks while reducing energy usage.

-

The Importance of Benchmarking Your Application Parameters

Having repeatability issues in your coating process? John Owed of Carlisle Fluid Technologies discusses the importance of benchmarking your application parameters in order to identify and quickly resolve problems.