Chemeon’s eTCP Offers Visual Verification for Coated Parts

Coating has safe trivalent chemistry and distinctive violet-blue hue.

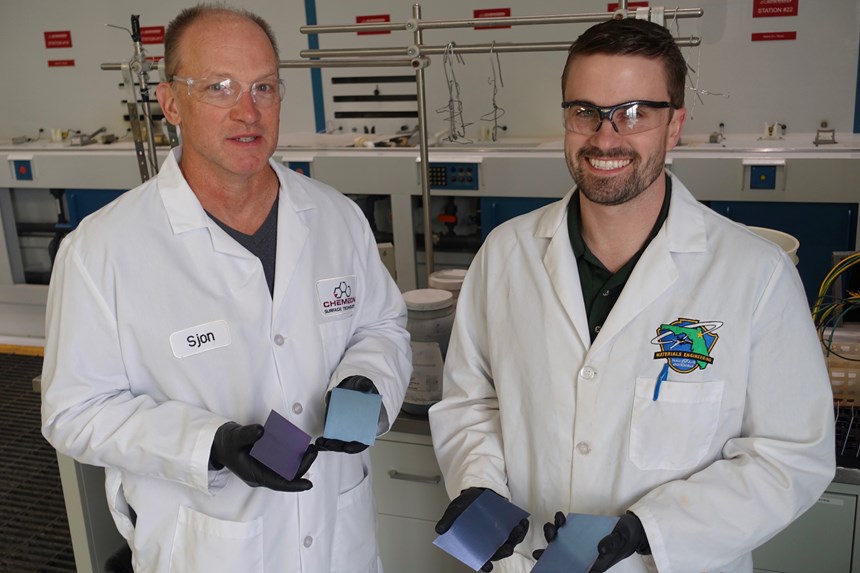

Chemeon Surface Technology knew it needed to find another way to help pretreatment users move away from hexavalent chromium coatings. While hexavalent chrome has an identifiable yellow-gold hue, TCPs have been colorless or nearly so. Chemeon has a patent pending with its eTCP chemistry that provides a distinct visual colorization that indicates aluminum and other light metal parts are coated and protected.

“There is a substantial quality control problem if you can’t tell the coating has been applied,” says Dr. Sjon Westre, vice president of technology at Chemeon. “In the past, we’ve relied on training and spot tests to answer that concern, but the lack of color has been a large barrier to implementation.”

Featured Content

Chemeon currently offers a hex-free product (TCP-HF) that has approvals for many aerospace and military applications. The eTCP is a colored version of TCP-HF that it developed to exhibit visual identification for quality control purposes. “Our invention solved the problem of creating a color, while still providing very good performance,” says Westre. “The corrosion protection of eTCP is quite a bit better than the TCP coatings.”

The product protects aluminum and other light metals from corrosion by chemically transforming the outer portion of the metal surface into a protective layer. It also leaves a base on the surface finish to provide better adhesion for organic coatings and preserve electrical conductivity.

"Chemon eTCP represents the evolution of trivalent chromium pretreatments,” says Dr. Madylon Meiling, Chemeon CEO. “One look and you know that your parts are protected."

The product exceeds MIL-DTL-5541 and MIL-DTL-8170 requirements for corrosion protection, electrical resistance and adhesion, and beta testing has had some noteworthy results.

Peter Sheridan, a senior materials engineer with the Naval Air Systems Command (NAVAIR) and the Fleet Readiness Center Southeast (FRCSE), is working with Chemeon under a cooperative research and development agreement to implement eTCP.

“For our organization, the end goal is to achieve a smooth transition away from hexavalent chromium conversion coatings and eTCP provides an avenue for that,” Sheridan says.

Westre says Chemeon has been able to improve the performance of the coating over the traditional TCP coatings, in particular, salt fog corrosion resistance. “Some end users discovered during head-to-head testing that the old reliable hex chrome coatings were not giving as good protection as they thought,” he says.

Application options include room-temperature immersion/dipping, spray, brush and pen. A ready-to-use product is convenient for customers doing spray applications such as aircraft prepaint, according to Westre. Chemeon has also developed a cleaning pen so users can apply a cleaner to a repair area, rinse the area and then use the TCP or eTCP pen to repair the spot. While traditional cleaning methods (sanding, scrubbing and rinsing) can still be used, the cleaner pen can be more convenient. “When you consider how and where touchup pens are used, the TCP and eTCP touchup pens are a tremendous improvement in worker safety,” says Westre.

RELATED CONTENT

-

Aluminum Anodizing

Types of anodizing, processes, equipment selection and tank construction.

-

Deoxidizing Aluminum as a Pretreatment

This important first step can help prepare the metal for subsequent surface finishing.

-

How to Apply the 720 Rule to Current Density Anodizing

What can you tell me about the 720 Rule as it applies to current density anodizing? Plating expert Sjon Westre, Ph.D., from Chemeon, answers this question.