Hexavalent-Chromium-Free Aluminum Sacrificial Paint Validation

Hexavalent chromium is a known carcinogen, repro-toxin and mutagen. Its elimination is of high importance to the aerospace industry, which has struggled to find high performing alternatives. Legacy aluminum sacrificial paints have traditionally utilized hexavalent chromium to prevent corrosion and coatings which are equal to or better than have been difficult. This second of two papers discusses the hexavalent-chromium-free process from the user point-of-view in terms of the process validation work by Rolls Royce Corporation.

#aerospace #nasf #surfin

A Paper* based on a Presentation given at NASF SUR/FIN 2022 (Rosemont, Illinois)

by

Brad Wiley**

Materials Technology Center

Rolls-Royce Corporation

Indianapolis, IN, USA

Featured Content

Editor’s Note: The following is a paper based on a presentation given at NASF SUR/FIN 2022, in Rosemont, Illinois on June 7, 2022, in Session 1, Aerospace / Defense Response to REACh. This is the second of two papers on the development of hexavalent-chromium-free aluminum sacrificial paints, this one from the user point-of-view – the process validation. The first, by McMordie, available at http://short.pfonline.com/NASF23Feb1, addresses the developer point-of-view. A pdf of this article can be accessed and printed HERE; the complete Powerpoint presentation is available by clicking HERE.

ABSTRACT

Hexavalent chromium is a known carcinogen, repro-toxin and mutagen. Its elimination is of high importance to the aerospace industry, which has struggled to find high performing alternatives. Legacy aluminum sacrificial paints have traditionally utilized hexavalent chromium to prevent corrosion and coatings which are equal to or better than have been difficult. Many attempts have resulted in failure. In this paper, a body of results will be shared substantiating efficacy of a leading replacement. Performance testing included cyclic-synthetic-seawater (salt spray/humidity/ambient) corrosion testing, continuous neutral salt spray corrosion testing, cyclic salt spray / humidity corrosion testing, cyclic salt spray / heat / humidity corrosion testing, heat resistance testing, fluid resistances testing, adhesion testing, conductivity/resistivity, metallography, quality, stripping, and touch up.

Introduction and background

Hexavalent chromium is a known carcinogen, repro-toxin, and mutagen. Its elimination is of high importance to the aerospace industry which has struggled to find high performing alternatives. Legacy aluminum sacrificial paints have traditionally utilized hexavalent chromium to prevent corrosion and oxidation of steels. Due to the high performance nature of these coatings, work to approve alternate coatings has been difficult. To date, most attempts have failed. A concurrent paper by McMordie, available at http://short.pfonline.com/NASF23Feb1, addresses the work involved in the product development of a leading replacement, a novel proprietary hexavalent-chromium-free aluminum sacrificial paint, Alseal 5KGT, developed by Coatings For Industry, Inc. (CFI), of Souderton, Pennsylvania. This paper covers the work toward successfully validating the product by the user, Rolls Royce Corporation.

Aluminum Sacrificial Paints (ASPs) have been used by the aerospace industry for decades to protect steel from corrosion and oxidation. A hexavalent chromium-free alternate to the traditional ASP systems (traditionally containing hexavalent chromium as a critical part of their binder system) has been a challenge for materials engineering in the aerospace industry for decades. Rolls-Royce Corporation has evaluated alternates; however, the latest data is promising that this challenge can be met. Coatings for Industry’s Alseal 5KGT, and its historical progenitors, have been evaluated over the years by Rolls-Royce Corporation. This paper summarizes the trials performed by Rolls-Royce Corporation and the favorable data it has generated.

Traditional ASPs are a layer of aluminum powder held against steels by a ceramic binder system. In many instances, this “base coat” is aided by an additional “sealer” layer, which is the binder system (only) applied over top as a barrier. Notably, it also acts to passivate the base coat. This system allowed for improved protection as well as providing coloration if desired. Given that hexavalent chromium is one of two components in the inorganic polymeric binder architecture, a novel binder system has been very challenging, not just within the base coat system but also with respect to the ability of the seal coat to passivate. Coatings for Industry’s novel approach to provide a base coat polymer architecture but also to overcome the challenges associated with the seal coat and its important function as a passivating layer has been a boon.

Rolls-Royce recognizes that the nature of the novel coating requires the base and seal coats to perform as a system; that they not be used independently and specifies this. Rolls-Royce tested this novel coating system against typical performance requirements required to approve traditional ASPs (containing hexavalent chromium) and to demonstrate results which exceed these requirements.

The performance tests focus on corrosion resistance but must include full characterization of the thermal limits of the coating. The tests performed include:

- Adhesion

- Corrosion resistance:

- Continuous neutral salt spray per ASTM B 117

- Cyclic synthetic sea-water humidity (US Navy test)

- Cyclic salt spray and heat

- Cyclic salt spray, humidity, and heat

- Throwing power

- Thermal resistance testing followed by continuous neutral salt spray testing

- Electrical properties (conductivity of base coat and non-conductivity of seal coat)

- Metallography

- Touch up

- Strip and recoat

- “Throwing Power”

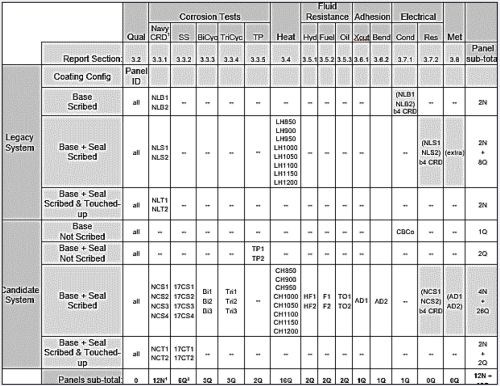

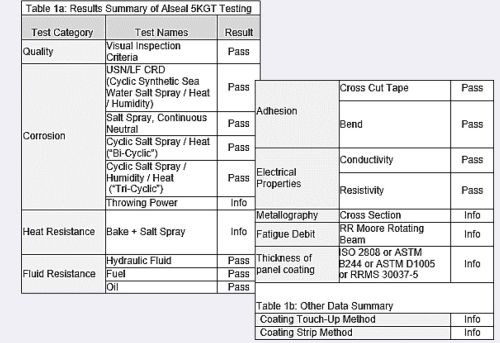

The test matrix is shown in Figure 1. The testing was designed to compare the legacy aluminum sacrificial paint containing hexavalent chromium with the chromium-free Alseal 5KGT candidate system. While the pass/fail performance data for the legacy system was well established in industrial practice, a number of the more rigorous military and aerospace specifications required concurrent side-by-side comparison.

Figure 1 - Test matrix used to evaluate performance of legacy Al sacrificial paint with Alseal 5KGT paint.

Corrosion testing

Corrosion test results are shown in Figs. 2 thru 6. The ASTM B-117 continuous neutral salt spray (Column “SS” in Fig. 1) was run for 1,008 hours, or 42 days. Scribed Alseal 5KGT panels were examined at intervals of 24, 96, 204, 504 and 1008 hours of exposure, and passed inspection. The results for panel 17CS1 are shown in Fig. 2.

NSS - 42-Day Exposure.jpg;maxWidth=720)

Figure 2 – ASTM B-117 42-day neutral salt spray performance result for scribed Alseal 5KGT, examined at specified intervals.

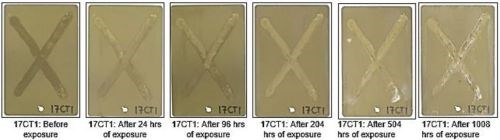

Additional scribed panels were touched up after scribing and subject to the 42-hour NSS; the results for panel 17CT1 are shown in Fig. 3.

Figure 3 – ASTM B-117 42-day neutral salt spray performance result for scribed and touched-up Alseal 5KGT, examined at specified intervals.

Referring to Figure 1, the “BiCyclic” corrosion test involved 20 days of salt spray and thermal cycling, while the “TriCyclic” corrosion test involved 10 days of salt spray, humidity, and thermal cyclicing. The test specimens were examined at several intervals and passed both tests satisfactorily. The BiCyclic and TriCyclic test results are shown in Figs. 4 (Sample Bi1) and 5 (Sample Tri1), respectively.

Bicyclic - 20-Day Exposure.jpg;maxWidth=720)

Figure 4 – BiCyclic corrosion / thermal cycling performance result for scribed Alseal 5KGT, examined at specified intervals.

Tricyclic - 10-Day Exposure.jpg;maxWidth=720)

Figure 5 – TriCyclic corrosion / thermal cycling performance result for scribed Alseal 5KGT, examined at specified intervals.

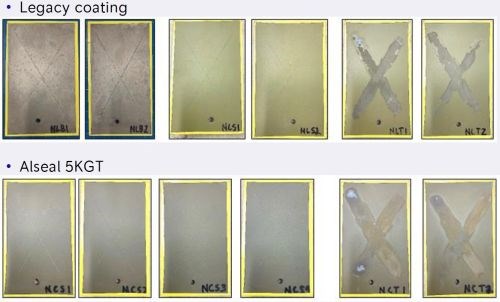

Navy corrosion testing was performed against the standard US Navy Components Requirements Document which instructs for a complex 50-day cyclic test including ambient, heating, humidity and synthetic sea water salt spray. Figure 6 shows the comparative results for both the legacy and Alseal 5KGT paints for (1) base coat with no seal, scribed, (2) base coat plus seal, scribed, and (3) base coat plus seal, scribed, and touched up. Alseal 5KGT performance was equal or better than the legacy system.

Figure 6 – Coated steel panels after 50-day U.S. Navy cyclic test. The first pair of panels in each row were coated with sacrificial basecoat alone (with no seal coat) and scribed, the second pair of panels were coated with sacrificial base coat and seal coat and then scribed, the third pair of panels were coated with sacrificial base coat, sealed, scribed and then touched up. Performance of Alseal 5KGT (lower row) was equal to or better than that of the legacy system (top row)

A Throwing Power corrosion test was developed by the author to attempt to determine the extent of protection afforded to the un-coated base metal surfaces due to adjacent coating. A triangular segment of the coating was stripped from a panel coated with Alseal AKGT. The panel was then subjected to salt fog. The novel coating prevented corrosion of bare steel up to ~0.030” from the coating edge.

Thermal resistance

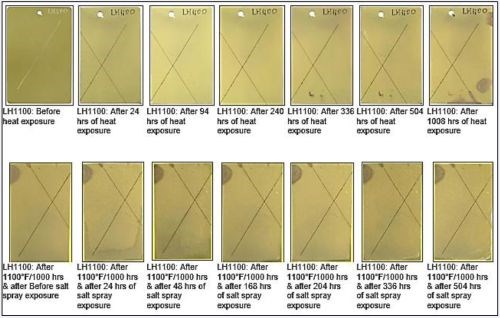

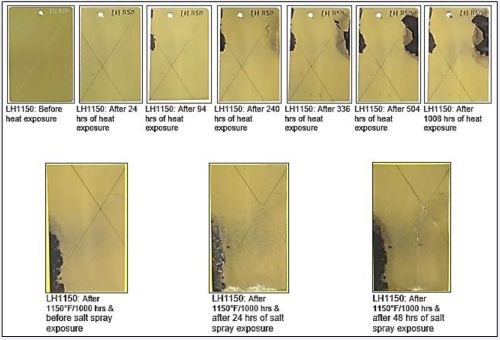

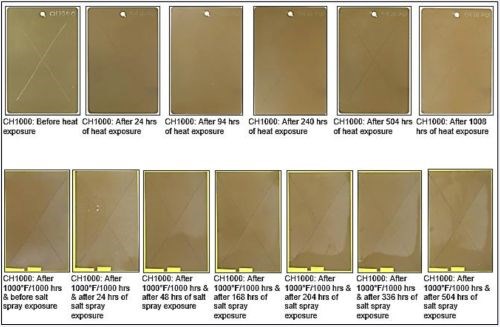

The thermal resistance study for the legacy coating involved a 42-day (1008-hr) thermal exposure at 1100°F. followed by neutral salt spray exposure. The results are shown in Fig. 7, for various intervals over the heat exposure process. The neutral salt spray exposure was 21 days (504 hr). Increasing the exposure temperature to 1150°F caused deterioration of the coating and the salt spray exposure was terminated at 48 hr (Fig. 8).

Figure 7 – Thermal resistance study of the legacy coating at 1100°F.

Figure 8 – Thermal resistance study of the legacy coating at 1150°F.

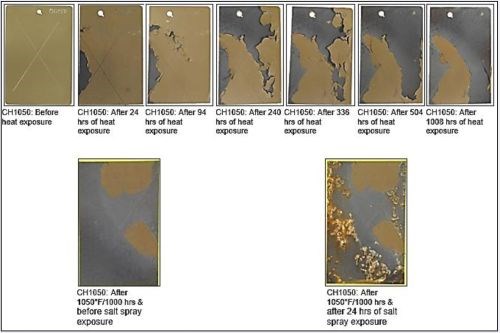

Thermal resistance performance of the Alseal 5KGT is shown in Figs. 9 and 10, for exposure temperatures of 1000°F and 1050°F, respectively. As before, the salt spray for the higher temperature was discontinued after 48 hours, with deterioration of the coating.

Figure 9 – Thermal resistance study of the Alseal 5KGT coating at 1000°F.

Figure 10 – Thermal resistance study of the Alseal 5KGT coating at 1050°F.

Results summary

The complete test results are summarized in Fig. 11. Where the Alseal 5KGT passed performance requirements, the novel hexavalent chromium-free was shown to have met the established criteria for visual quality, corrosion resistance, fluid resistance, adhesion and electrical properties. The other results, including heat resistance, are reported for information. In general, the results indicate success for many applications.

Figure 11 – Summary of test results.

About the author

Brad Wiley is Chemical Process Specialist and member of the Materials Technology Center within Materials Engineering at Rolls-Royce Corporation, Indianapolis, Indiana. He began his career as a plating chemist, has been a metallurgist, a chemical process engineer, repair engineer within the aftermarket validating repair and overhaul of engine components, and in 2010 moved to his current position as a researcher responsible for chemical processes as well as Rolls-Royce’s global paint strategy.

*Compiled by Dr. James H. Lindsay, Technical Editor - NASF

** Corresponding author:

Brad Wiley, Chemical Process Specialist

Rolls Royce Corporation

1875 S. Tibbs Ave.

Indianapolis, IN 46241

Phone Office: (317) 292-7368

Phone Mobile: (317) 292-7368

E-mail: brad.wiley@rolls-royce.com

RELATED CONTENT

-

Trivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

-

Development of a Novel Hexavalent-Chromium-Free Aluminum Sacrificial Paint

Hexavalent chromium is a known carcinogen, repro-toxin, and mutagen. Its elimination is of high importance to the aerospace industry, which has struggled to find high performing alternatives. Legacy aluminum sacrificial paints have traditionally utilized hexavalent chromium to prevent corrosion and coatings which are equal to or better than have been difficult. This first paper discusses the novel process from the supplier point-of-view.

-

Bryan Leiker, MFACA, Discusses CARB Public Hearing Over Calif. Hex Chrome Ban

Bryan Leiker, executive director, Metal Finishing Association of California, offers a recap of a January 27, 2023, public hearing conducted by the California Air Resources Board prior to an impending ruling on a proposed ban of hexavalent chromium use for finishing operations in the state.