Steelhead has made Veterans Metal’s processes much more efficient by integrating iPads and a QR code system. Plant Manager and Navy veteran, Randy Wayand, uses the new system on Veterans Metal’s shop floor. Photo Credit: Steelhead Technologies

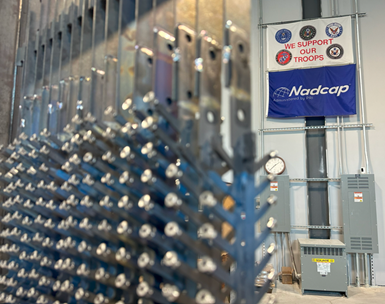

When Andrew Kossowski acquired the former DHS Enterprises (Clearwater, Florida) in September 2020, the 27-year-old shop was 100% manual with no ability to track efficiency or performance quality. From the beginning of his ownership, however, Kossowski envisioned a complete makeover of the entire business. His first step was to complete the National Aerospace and Defense Contractors Accreditation Program (NADCAP) accreditation for Anodizing and Quality Management System in the old shop, which the shop accomplished in August 2022. It also obtained a Lockheed certification for various other processes at that time. The next step was starting from scratch with new equipment,moving out of the old 5,000-square-foot facility and building a new 15,000-square-foot building, including a complete digital transformation end to end.

The new company, Veterans Metal, contains no paper trails but instead, full digital traceability. When the new shop officially opened with a ribbon-cutting ceremony at its new location in August 2023 in Largo, Florida, it was already well on its way to becoming paperless, proving to Kossowski that it pays off to dream big.

Featured Content

By implementing Steelhead Technologies’ customizable ERP software, the 16-employee shop — which offers its customers a variety of finishes including anodizing, chem film and passivation — has found that it can more easily maintain its demanding NADCAP certification while eliminating Excel spreadsheets and traveler carts. Steelhead combines quoting systems, scheduling and invoice tracking for the shop.

“The process that we captured from the last time we worked on the part is already in the software,” Kossowski explains. “I used to type the same information three times. And then I had to use a pen and paper to write things down. The worst thing about pen and paper is that people can write whatever they want.” But now, with the shop’s use of iPads and QR codes, part tracking is much more accurate and avoids human error, he adds.

Working without paper has made Kossowski consider how much time was wasted filling out forms. “We can be better by doing other things like focusing on the job, how to make the part properly and focusing on strategy in processing the part.”

The entire project — from the initial regular meetings to discuss Veterans Metal’s needs through the development stages and testing of the software to the integration of the technology — was completed in about 10 months. Although it has only been implemented for a short time so far, Kossowski is already ecstatic about the impact Steelhead has had on his business.

A perfect pair

Finding job shop software specifically for anodizing or the metal finishing processes Veterans Metal offers for the military, automotive and marine industries was

Even though the shop had not yet implemented Steelhead at 100% capacity, it completely stopped using paper to document NADCAP on Sept. 1, which was made possible by QR technology. Photo Credit: Veterans Metal

challenging for Kossowski, simply because there are not many options on the market, he says. Therefore, when he discovered Steelhead at the International Manufacturing Technology Show in 2022, he was anxious to learn more about its offerings. After a long discussion about goals and objectives, both the shop and software developer felt they were a great match for one another.

According to Chet Halonen, sales engineer at Steelhead, the project was promising from the get-go. He says the team discussed Kossowski’s goals for digital integration and all the functionality that Veterans Metal was looking for.

Kossowski has similar sentiments about their initial meeting. “I immediately realized they were exactly what I was looking for,” he comments. He adds that he was impressed with the people he met, including Halonen and later the CEO, Jeff Halonen. “They have done a marvelous job. I particularly like their project management approach and the implementation of the project,” he says.

With an undergraduate degree in aeronautical science and a graduate degree in computer science, Kossowski had a good understanding of the language Steelhead spoke. He had also managed many large-scale projects and programs in the corporate world before his time at Veterans Metal and after his military career in the U.S. Air Force, where he worked primarily in testing and quality assurance for the manufacturing and refurbishment of a variety of aircraft.

He also respected that Steelhead’s staff knew its products well. The sales staff understood the technical aspects of the product and could answer his questions intelligently. “That was really important to me from a confidence perspective and getting the project done.”

According to Halonen, Steelhead has been excited about working with the team at Veterans Metal from the beginning and describes the shop as “leading the charge” in the NADCAP space. Although it is the software company’s first time developing programs specifically to adhere to this certification for a customer, it is no stranger to this certification. Its team of 11 full-time developers understand the importance of NADCAP and how it influences its customers. As a result, the company had been working toward building infrastructure around this demanding accreditation prior to working with Veterans Metal.

However, the Steelhead company itself is not NADCAP accredited. “Veterans Metal is our customer, and we work to its requirements, and they are responsible for being NADCAP accredited,” Halonen says. “At the end of the day, we are not doing NADCAP processing. So, we don’t have any formal ties with it or the Performance Review Institute (the organization that administers the accreditation).”

From planning to beta testing

Because of the robust documentation and adherence to procedures that are necessary for NADCAP audits, Veterans Metal understood digitizing its entire ecosystem would be a challenge that would take time, patience, trial and error, and persistence. But in the long run, it would be worth the work; going

paperless not only adds efficiency to the shop floor, but also produces more reliable and predictable data that is valuable to the shop and its aerospace and defense customers.

Kossowski also intended for Steelhead to mold a new way of thinking for Veterans Metal. “There's no point in spending money on software that will only replicate what you had before,” he explains. “There's a lot of bells and whistles when it comes to technology, and I want to take advantage of those without customizing the software to a point where it's unrecognizable. So that was a priority for me and my team to not ask Steelhead to modify anything to fit some old way of thinking.”

Therefore, from the beginning, Kossowski was open to being a beta tester for the technology, which pleased Steelhead and gave the shop the privilege of helping customize the software. They agreed to begin a rollout on Jan. 1, 2023, (at the old shop because the new one was not built yet) with the additional help of Veterans Metal employees who were knowledgeable about various aspects of the shop’s production process. The team set out to meet one to two times per week.

The team’s digitization goals included eliminating paper travelers on the shop floor, tracking parts throughout every stage of processing as well as enabling awareness of the areas of the company that are making money and losing money. It was also critical for the software to integrate many systems, including inventory tracking and quoting.

Veterans Metal tanks are used in the metal finishing process with QR codes for NADCAP tracking and repeatability via Steelhead. Photo Credit: Veterans Metal

As Halonen and the software team consulted with the shop’s team members, they gradually built features and modules for the software. Then, the entire group went through a two-month testing process on site at the shop to ensure the software functioned properly and contained the necessary elements.

QR scanning changes perspective

As a result of the close partnership with Veterans Metal, Steelhead created the Certification Scanner Line for the shop (now on the market for any NADCAP metal finishing shop). This technology streamlines data entry and employs advanced algorithms to ensure data accuracy. The systems are designed to flag anomalies and deviations from industry standards without human intervention. Everything is done at the click of a button with a QR scanner gun and integrated system.

In a NADCAP environment where operator instruction and time tracking are required, like at Veterans Metal, the Scanner Line is most valuable. Here, all different parts from multiple customers are loaded onto a rack that has a QR code, as do the stations. A handheld scanner is used to instruct operators on when to move parts and to where, while simultaneously recording all the processing history required by NADCAP, military and other accreditations, Jeff Halonen explains.

Through Steelhead, certifications are fully digital and can be created in a fully automated fashion, pulling information from processing, receiving, inventory, specifications, measure data, photos and more. The digital certifications can be sent to customers directly from the platform.

The software team started automating the invoicing/quoting process first since Veterans Metal wanted to use QR codes for this in the new shop where it was slated to move at the end of July. So, getting an early start, the developers integrated the existing Excel spreadsheets with algorithms Kossowski himself created into the new software. Now, when performing a preliminary inspection, the department uses QR scanners and iPads instead of tracking everything on paper.

Training and champions

Backing up to Aug. 3, the day of Veterans Metal’s ribbon cutting ceremony, the shop also held its first training session for all Veterans Metal employees with Steelhead present. In addition to the five to six hours of training the software developers conducted that day, training continued throughout August via several video conference calls. The company set up 50-inch TV screens on the shop floor and provided an environment for remote interaction with Steelhead.

Training has been conducted in stages as the technology for each department has been rolled out. To aid in a smooth training process, Kossowski assigned two champions and funneled training through them. One champion, who is the assistant office manager, heads up the quoting, shipping and receiving and invoicing departments while the other, who is the plant manager, focuses on quality inspections, racking and packing the process line. By dividing training between two champions, they had the opportunity to ask questions, determine any bugs and make enhancements to the application prior to introducing the training to the rest of the team.

The all-employee training sessions with Steelhead were also valuable. If there were additional questions, employees didn't have to wait for an answer from the champion; they could ask Steelhead on the spot.

A bright future

Thrilled with how the software has made the shop’s NADCAP documentation so much more efficient, which improves the overall workflow and time savings on the shop floor, Kossowski and the Veterans Metal team are excited to continue working closely with Steelhead — a company that can keep up with their fast pace.

Because the shop is an early adopter of the software and Steelhead is an early-stage company, Kossowski believes there is still a lot of growth potential ahead for the partnership. For example, he plans to increase capacity from the old shop’s 100,000 parts processed per month to potentially three million parts and to increase the number of employees to 30.

“We’re going to add more NADCAP accredited services with the support of Steelhead software — we’re not done,” he says. “We have a lot to offer Steelhead because we’re growing. And they are not set in their ways. They can adapt and be flexible right now.”

RELATED CONTENT

-

Assessment of Safer Polysulfide and Polythioether Sealant Removers for Aerospace/Defense Industry Applications

This assessment identifies and evaluates potentially safer alternatives for sealant removal applications. The sealant removal performance of the alternatives was evaluated using a designed experiment.

-

Digitizing Your Job Shop for Increased Production and Profitability

Dean Halonen of ERP software provider Steelhead Technologies discusses how digitizing your metal finishing job shops can help you achieve more production throughput and improve profitability.

-

ERP for Finishing Companies

Robert (Bobby) Haggard, consultant for TrinSoft LLC, discusses the growing need for all-inclusive ERP solutions for finishing operations.