NASF/AESF Foundation Research Project #121: Development of a Sustainability Metrics System and a Technical Solution Method for Sustainable Metal Finishing - 9th Quarterly Report

This NASF-AESF Foundation research project report covers the ninth quarter of project work (April June 2022) at Wayne State University in Detroit. The major activities in this report period are: (1) refinement of the sustainability assessment method for technology evaluation with case studies, (2) development of a journal paper and one conference paper, and (3) a presentation at NASF SUR/FIN 2022 in Rosemont, Illinois.

#nasf #surfin #sustainability

by

Yinlun Huang*

Department of Chemical Engineering and Materials Science

Wayne State University

Detroit, Michigan, USA

Editor’s Note: This NASF-AESF Foundation research project report covers the ninth quarter of project work (April-June 2022) at Wayne State University in Detroit. A printable PDF version of this report is available by clicking HERE.

Featured Content

It is widely recognized in many industries that sustainability is a key driver of innovation. Numerous companies, especially large ones who made sustainability as a goal, are achieving clearly more competitive advantages. The metal finishing industry, however, is clearly behind others in response to the challenging needs for sustainable development.

This research project aims to:

- Create a metal-finishing-specific sustainability metrics system, which will contain sets of indicators for measuring economic, environmental and social sustainability,

- Develop a general and effective method for systematic sustainability assessment of any metal finishing facility that could have multiple production lines, and for estimating the capacities of technologies for sustainability performance improvement,

- Develop a sustainability-oriented strategy analysis method that can be used to analyze sustainability assessment results, identify and rank weaknesses in the economic, environmental, and social categories, and then evaluate technical options for performance improvement and profitability assurance in plants, and

- Introduce the sustainability metrics system and methods for sustainability assessment and strategic analysis to the industry.

This will help metal finishing facilities to conduct a self-managed sustainability assessment as well as identify technical solutions for sustainability performance improvement.

1. Student participation

Abdurrafay Siddiqui, a Ph.D. student, has been continuously guided by the P.I. to work on the project. In this project reporting period, the student was fully supported by Wayne State University as a Graduate Teaching Assistant (GTA) until May 10, and then jointly supported by the AESF project and a National Science Foundation project. One undergraduate student, Rebecca Potoff, a senior student of chemistry at SUNY Binghamton University, was continuously hired by the P.I. as an NSF Undergraduate Research Assistant (URA), for the project until May 10, 2022.

2. Project activities and progress

The major activities in this report period are: (1) refinement of the sustainability assessment method for technology evaluation with case studies, (2) development of a journal paper and one conference paper, and (3) a presentation at NASF SUR/FIN 2022 in Rosemont, Illinois. Each of these is briefly reported below.

2.1 Case study on sustainability evaluation of electroplating facilities

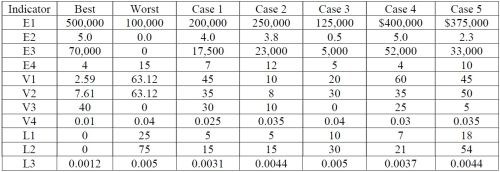

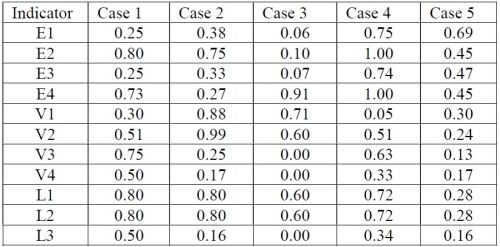

The sustainability metrics system and the assessment method, which were reported in the last quarterly report (Quarter 8), were applied to the study of five electroplating facilities. The economic, environmental, social and overall sustainability performances of each facility were assessed and graphically compared. A total of 11 sustainability indicators were chosen from the sustainability metrics system that was developed by the P.I., for the assessment. These include four economic indicators, four environmental indicators and three social indicators. The indicators are listed in Table 1. The case study data was collected from previous studies undertaken by the P.I.’s group (Song, et al., 2016; Xiao and Huang, 2012; Xu, et al., 2005; Yang, et al., 1999; Yang, et al., 1999) as well as the National Center for Manufacturing Sciences’ benchmarking survey for the electroplating sector (NCMS, 2000). This data is summarized in Table 2, which were reported in the past quarterly report as well. In this report period, the data was normalized for each indicator, which is shown in Table 3. These indicator values for different cases are plotted using the radar chart in Fig. 1. The overall sustainability performance for the five cases is shown in the sustainability cube of Fig. 2.

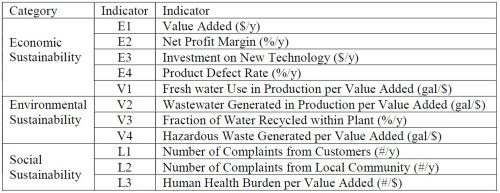

Table 1 - Selected indicators for case study.

Table 2 - Case study data for indicator value evaluation.

Table 3 - Normalized indicator values of different cases.

Figure 1 – Indicator-specific performance comparison of five cases: (a) economic sustainability, (b) environmental sustainability and (c) social sustainability.

Figure 2 - Comparison of overall sustainability performance of the five cases under study (before technology implementation).

2.1.1. Implementation of sustainable technologies for performance improvement. After analyzing the sustainability performance of the five cases, we selected two technologies to test the effectiveness for performance improvement of each case. As reported in the last quarterly report, the technologies are:

Tech 1 (T1) – Chemical Concentration Optimization (CCO) Technology. The key components of the technology are: (a) a first principles based dynamic model for cleaning units performing alkaline, acid or electrocleaning operations, and (b) an optimal operation strategy for determining optimal chemical settings in different cleaning units. This CCO technology can help reduce chemical consumption, lower chemical loss to the succeeding rinsing units, and thus lower the chemical concentration in wastewater while the cleaning quality can always be guaranteed.

Tech 2 (T2) – Optimal Water Use and Reuse (OWUR) Technology. This technology was developed using system modeling and optimization techniques. A fundamental rinsing system model could provide the necessary information for redesigning a rinsing system if necessary, and for determining an optimal setting of each freshwater flow and for guiding water reuse before being discharged to a wastewater pretreatment facility in a plant. This technology could significantly reduce the consumption of freshwater and the volume of wastewater, and lower wastewater treatment cost, while the rinsing quality in different operational steps can be ensured.

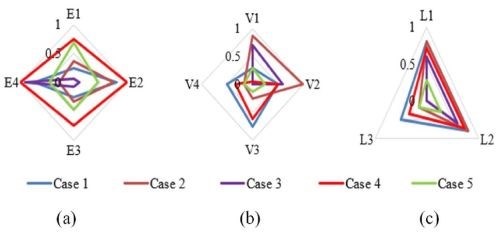

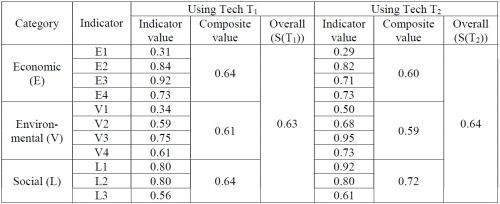

We studied technology application potential for sustainability performance improvement for all five facilities, which are named five cases. Taking Case 1 as an example, the effectiveness of using the technologies T1 and T2 are summarized in Table 4, where the values are all normalized. Comparing with the indicator values of Case 1 before technology implementation in Table 3 (the 2nd column), the indicator values after using T1 are all improved, except for three (V3, L1 and L2) that are unchanged (see the 3rd column in Table 4). If using T2, a total of ten indicator values are improved , with one (L2) unchanged. Furthermore, we found that the economic sustainability after using T1 (i.e., 0.64) is clearly better than the result using T2 (0.60), while the social sustainability if using T2 clearly shows a more significant improvement as compared to that if using T1 (see 0.72 vs 0.64). For real application, the facility management can decide which technology is more attractive, based on its business goal. Figure 3(a) plotted the results in a sustainability cube.

Table 4 - Plant sustainability performance after technology adoption in Case 1.

Figure 3 - Comparison of overall sustainability performance of the five cases studied (after implementation of technologies T1 and T2).

We have completed the study of the other four cases (i.e., Cases 2 to 5). The categorized sustainability (E, V, and V) values and the overall sustainability (S) values are plotted in Fig. 3(b) to 3(e).

2.2 - Presentation and publication activities.

We presented a paper, entitled “Technology Assessment for Sustainability Performance Improvement in Metal Finishing Facilities”, in Session 8 - Innovations for Improving Productivity at the NASF Sur/Fin 2022, in Rosemont, Illinois, on June 8, 2022. The paper was co-authored by Abdurrafay Siddiqui (Ph.D. student), Rebecca Potoff (undergraduate student) and Yinlun Huang. A copy of the presentation slides can be downloaded HERE.

We have generated a draft paper, “Sustainable Technology for Metal Finishing Facilities: A Comprehensive Assessment and Decision Making Method.” It is to be submitted to the Journal of Cleaner Production, which has possibly the highest impact factor (9.297) in the field.

We also submitted an abstract, entitled “Plant-wide Digital Twinning of Surface Finishing for Sustainable Manufacturing,” for presentation at the AIChE Annual National Meeting in Phoenix, Arizona, November 13-18, 2022. The paper is co-authored by Abdurrafay Siddiqui (Ph.D. student), Mahboubeh Moghadasi (Ph.D. student) and Yinlun Huang. The abstract is as follows:

“The surface finishing industry is critical to many manufacturing industries, such as automotive, aerospace, electronics, defense, as well as a variety of OEMs. This is because the finish on a surface can make a huge effect on the performance, durability, and/or aesthetic appearance of the parts that are used in those industries. The surface finishing industry has been highly regulated by EPA due to its significant use of numerous toxic/hazardous chemicals and the generation of huge amounts of waste in various forms; this could be very harmful to the environment, human health and communities, as well as facilities’ financial performance.

While significant progress has been made to improve the sustainability performance in the industry over the past two decades, the consumptions of chemical, water and energy are still too high, there still exist various environmental and health risks, and profit margin is still very low in a large number of plants. One of the solution approaches is firstly to characterize the dynamic behavior of electroplating lines under different operating conditions with uncertainty. Digital twinning is a powerful technique in Industry 4.0. A digital twin is a virtual representation that serves as the real-time digital counterpart of a physical process system. In this paper, we introduce a framework for generating a set of neural-networks-based digital twins for characterizing pre-surface preparation, surface finishing, and post-surface processing of a zinc electroplating line. Using large sets of plant data, the digital twins are created by resorting to a supervised learning technique; they will be updated as new plant data become available. We will show how the

developed digital twins can be employed to analyze plant’s sustainability performance and identify performance improvement opportunities.”

3. Plan for the 10th quarter of the project

Three tasks are planned for the next project period:

- We will identify additional technologies for technology assessment and conduct additional case studies.

- We will seek funding to support an undergraduate student to continuously develop the ISAE tool.

- We will submit a technical paper for publication in the Journal of Cleaner Production.

4. Bibliography

Benchmarking Metal Finishing, Report 0076RE00, National Association for Manufacturing Sciences (NCMS), Ann Arbor, MI, June 2000.

H. Song, N. Bhadbhade, and Y. Huang, “Sustainability assessment and performance improvement of electroplating process systems," in Sustainability in the Design, Synthesis, and Analysis of Chemical Engineering Processes (G. Ruiz-Mercado and H. Cabezas, eds.), Elsevier, 2016; Chapter 10 (pp. 227-248).

J. Xiao and Y. Huang, “Technology integration for sustainable manufacturing: an applied study on integrated profitable pollution prevention in surface finishing systems,” Industrial & Engineering Chemistry Research 51 (35), 11434-11444 (2012).

Q. Xu., A. Telukdarie, H.H. Lou and Y. Huang, “Integrated electroplating system modeling and simulation for near zero discharge of chemicals and metals,” Industry & Engineering Chemical Research, 44 (7), 2156-2164 (2005).

Y.H. Yang, H.H. Lou and Y. Huang, “Optimal design of a water reuse system in an electroplating plant,” Plating and Surface Finishing, 86 (4), 80-84 (1999).

5. Past project reports

1. Quarter 1 (April-June 2020): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 84 (12), 14 (September 2020); Full paper: http://short.pfonline.com/NASF20Sep1

2. Quarter 2 (July-September 2020): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 85 (3), 13 (December 2020); Full paper: http://short.pfonline.com/NASF20Dec1

3. Quarter 3 (October-December 2020): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 85 (7), 9 (April 2021); Full paper: http://short.pfonline.com/NASF21Apr1.

4. Quarter 4 (January-March 2021): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 85 (11), 13 (August 2021); Full paper: http://short.pfonline.com/NASF21Aug1.

5. Quarter 5 (April-June 2021): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 86 (1), 19 (October 2021); Full paper: http://short.pfonline.com/NASF21Oct2

6. Quarter 6 (July-September 2021): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 86 (4), 19 (January 2022); Full paper: http://short.pfonline.com/NASF22Jan3

7. Quarter 7 (October-December 2021): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 86 (7), 17 (April 2022); Full paper: http://short.pfonline.com/NASF22Apr2

8. Quarter 8 (January-March 2022): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 86 (10), 17 (July 2022); Full paper: http://short.pfonline.com/NASF22Jul2

5. About the Principal Investigator

Dr. Yinlun Huang is a Professor at Wayne State University (Detroit, Michigan) in the Department of Chemical Engineering and Materials Science. He is Director of the Laboratory for Multiscale Complex Systems Science and Engineering, the Chemical Engineering and Materials Science Graduate Programs and the Sustainable Engineering Graduate Certificate Program, in the College of Engineering. He has ably mentored many students, both Graduate and Undergraduate, during his work at Wayne State.

He holds a Bachelor of Science degree (1982) from Zhejiang University (Hangzhou, Zhejiang Province, China), and M.S. (1988) and Ph.D. (1992) degrees from Kansas State University (Manhattan, Kansas). He then joined the University of Texas at Austin as a postdoctoral research fellow (1992). In 1993, he joined Wayne State University as Assistant Professor, eventually becoming Full Professor from 2002 to the present. He has authored or co-authored over 220 publications since 1988, a number of which have been the recipient of awards over the years.

His research interests include multiscale complex systems; sustainability science; integrated material, product and process design and manufacturing; computational multifunctional nano-material development and manufacturing; and multiscale information processing and computational methods.

He has served in many editorial capacities on various journals, as Co-Editor of the ASTM Journal of Smart and Sustainable Manufacturing Systems, Associate Editor of Frontiers in Chemical Engineering, Guest Editor or member of the Editorial Board, including the ACS Sustainable Chemistry and Engineering, Chinese Journal of Chemical Engineering, the Journal of Clean Technologies and Environmental Policy, the Journal of Nano Energy and Power Research. In particular, he was a member of the Editorial Board of the AESF-published Journal of Applied Surface Finishing during the years of its publication (2006-2008).

He has served the AESF and NASF in many capacities, including the AESF Board of Directors during the transition period from the AESF to the NASF. He served as Board of Directors liaison to the AESF Research Board and was a member of the AESF Research and Publications Boards, as well as the Pollution Prevention Committee. With the NASF, he served as a member of the Board of Trustees of the AESF Foundation. He has also been active in the American Chemical Society (ACS) and the American Institute of Chemical Engineers (AIChE).

He was the 2013 Recipient of the NASF William Blum Scientific Achievement Award and delivered the William Blum Memorial Lecture at SUR/FIN 2014 in Cleveland, Ohio. He was elected AIChE Fellow in 2014 and NASF Fellow in 2017. He was a Fulbright Scholar in 2008 and has been a Visiting Professor at many institutions, including the Technical University of Berlin and Tsinghua University in China. His many other awards include the AIChE Research Excellence in Sustainable Engineering Award (2010), AIChE Sustainable Engineering Education Award (2016), the Michigan Green Chemistry Governor’s Award (2009) and several awards for teaching and graduate mentoring from Wayne State University, and Wayne State University’s Charles H. Gershenson Distinguished Faculty Fellow Award.

* Dr. Yinlun Huang, Professor

Dept. of Chemical Engineering and Materials Science

Wayne State University

Detroit, MI 48202

Office: (313) 577-3771

E-mail: yhuang@wayne.edu

RELATED CONTENT

-

Defects in Hard Chromium Deposits Part I: Causes and Cures

The causes of and remedies for defects in hard chromium deposits are explored in the first of this two-part P&SF article from 1984. Photomicrographs and SEM (scanning electron microscope) photographs will illustrate that most defects in various hard chromium deposits arise from defects in the basis metal. These defects may be in the original metal surface or may be caused by preplate finishing. Homogeneous hard chromium deposits can be produced only by eliminating these defects. Practical suggestions and procedures will be given.

-

Methods and Formulas to Determine Internal Deposit Stress in Applied Metallic Coatings

Internal stress exists in electroplated and chemically applied metallic coatings. This paper reviews the test procedures for measuring deposit stress and the formulas used to calculate stress values. Many formulas used require modification to obtain actual internal stress values. Errors in this regard are examined and common mistakes are explained.

-

Black Chromium Finishing: Beauty and the Beast

Over the past 10 years, there has been commercial development of black chromium deposits from a trivalent chromium electrolyte. This paper will review the deposit characteristics and operational consideration of these similar, but different chromium plating deposits.