Nanostructured Metal Coatings Let Light Through For Electronic Devices

New anti-reflection coating developed by engineers at University of Illinois at Urbana Champaign and the University of Massachusetts at Lowell.

#masking #pollutioncontrol

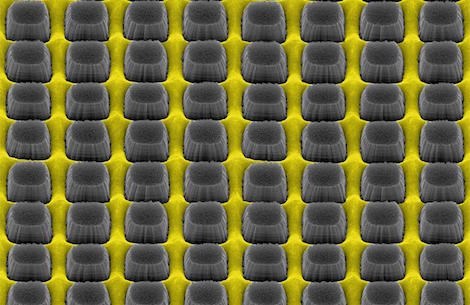

An array of nanopillars etched by thin layer of grate-patterned metal creates a nonreflective surface that could improve electronic device performance. Image Courtesy Of Daniel Wasserman.

Light and electricity dance a complicated tango in devices like LEDs, solar cells and sensors. A new anti-reflection coating developed by engineers at the University of Illinois at Urbana Champaign, in collaboration with researchers at the University of Massachusetts at Lowell, lets light through without hampering the flow of electricity, a step that could increase efficiency in such devices.

Featured Content

The coating is a specially engraved, nanostructured thin film that allows more light through than a flat surface, yet also provides electrical access to the underlying material - a crucial combination for optoelectronics, devices that convert electricity to light or vice versa. The researchers, led by U. of I. electrical and computer engineering professor Daniel Wasserman, published their findings in the journal Advanced Materials.

"The ability to improve both electrical and optical access to a material is an important step towards higher-efficiency optoelectronic devices," said Wasserman, a member of the Micro and Nano Technology Laboratory at Illinois.

To read more, please visit: http://www.eurekalert.org/pub_releases/2015-12/uoia-nmc120915.php

RELATED CONTENT

-

Reducing Powder Coating Waste

Coating application is often overlooked as a potential money saver, but recognizing opportunities within this area is crucial to an efficient operation.

-

Touch-up Options for Powder Coated Parts

Is it true that powder coating cannot be touched up? Powder coating expert Rodger Talbert offers options for powder coating touch-ups.

-

Dis-Charge Your Powder

A practical approach to managing electrostatic problems and hazards during powder coating