Fixing Salt Spray Failures After Passivating, Baking

This is a common challenge faced by many acid zinc platers who Mark Adams from Columbia Chemical says perform hydrogen embrittlement relief on acid zinc plated fasteners.

#ask the expert

Fixing Excessive Brightener Consumption From Dull Work In Alkaline Non-Cyanide Zinc

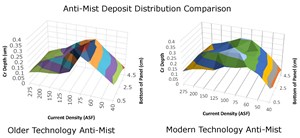

Although great strides have been made over the last 30 years in the development of alkaline non-cyanide zinc processes, Asterion’s Graham Torr says not all “modern” systems are created equal.

#ask the expert

Colloy A-Z-N 300 Addresses Common Plating Problem

By: Angela Osborne - Production Machining

Columbia Chemical replaces ammonium chloride/high salt content in older zinc-nickel systems.

Webinar Looks at Trivalent Chromium Process Capability Study for OEMs

By: Tim Pennington -

Mark Schario, executive vice president for Columbia Chemical, will present information on evaluating test matrix variables and performance results of exterior corrosion testing between trivalent and hexavalent.

#education

Preventing Dark Streaks in Trivalent Chromium

Matt Schario from Columbia Chemical explains what is the likely cause of these streaks and patterns, and how to prevent this from happening.

#ask the expert

Columbia Chemical TriCol Process Enables Fast Plating

Columbia Chemical’ s TriCol Décor process for trivalent chromium plating is chloride based for faster plating, according to the company

#pollution control

ColDip Midnight 1500 Black Zinc Passivate Offers Enhanced Color and Cost Control

By: Tim Pennington -

Three-part system allows for maximum color control and provides a consistent black appearance

Fixing The Cause Of Yellowing In Blue Trivalent Passivate

When parts look great upon initial make-up, but begin to yellow in appearance after 2-4 weeks, Chad Murphy from Columbia Chemical says it can be a number of factors.

How Trivalent Chrome Compares to Hexavalent

Columbia Chemical’s Mark Schario explains how the performance of trivalent chromium compares to hexavalent chromium, and what is needed to make the change to tri-chrome plating.

Converting to Trivalent Chrome from Hexavalent

Although this requires an initial time and cost investment, Columbia Chemical’s Mark Schario says the benefits of trivalent over hexavalent quickly and increasingly overcome the drawbacks.