Sweet Smell of Painting Success

Jet Metal’s unique inline metalization process is a hit with fragrance makers.

#masking #pollutioncontrol #curing

For Samuel Stremsdoerfer, coatings have always had the sweet smell of success, especially when the coated items are perfume and spirit bottles.

Stremsdoerfer is chairman of Jet Metal Technologies in France, a company which is working to break through in the U.S. with a unique inline metalization process that coats products—including bottles—by spraying them without using an electroplating or vacuum process.

Featured Content

In Europe, Jet Metal has carved out a niche in the coating of bottles and containers in the spirits, fragrances and cosmetic/care industries, working with customers such as Coty, Hennessy, L’Oreal, Louis Vuitton and Procter & Gamble.

“It’s a tremendous growth market,” Stremsdoerfer says of the fragrance and cosmetic sector. “We have a lot of interest in the process because of the overall benefits compared to other finishing processes.”

Jet Metal is also targeting the automotive sector on both interior and exterior finishes. The company is already working with PSA Peugeot Citroën and Renault as well as Nissan in Europe and General Motors in South America.

Growth Strategy

The company’s growth strategy includes ventures into the furniture, fixtures and electronic device markets, hoping to introduce a new coating system that may be greener and more cost-effective than traditional forms of plating such as galvanization and vacuum.

Sébastien Fourneron, Jet Metal’s associate director of sales and marketing, says the company offers metallic coatings such as copper, nickel/boron, silver, cobalt, iron/boron and nickel/iron as well as composite coatings shared between its decorative and functional departments.

“In decoration, metalization is becoming a quality and luxury guarantee on any fields,” he explains. “Our goal is to bring a technology solution to any metalization need.”

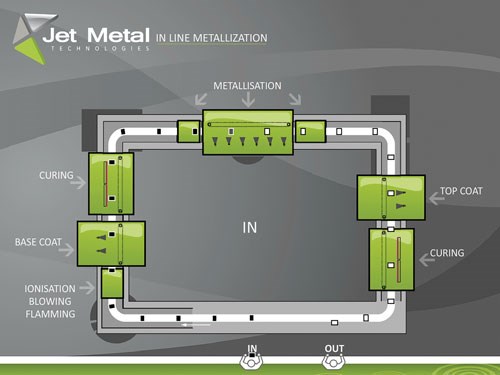

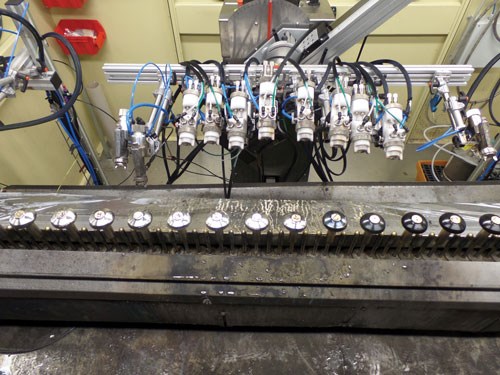

For all its distinctiveness, the technology is fairly straightforward. After a base coat is applied, a painting nozzle emits two propriety water-based solutions on substrates such as plastics, glass, aluminum or even zamak, which has a zinc base and alloying elements of aluminum, magnesium and copper.

The two aerosols contain a 3D-part-designed aqueous solution with metal cation—or metallic salt—and an aqueous solution with a reducing agent. A reduction-oxidation process begins on the substrate, followed by an instantaneous and homogeneous growth of a metallic layer. This is followed by a general topcoat.

Various Substrates

Stremsdoerfer said that, for the functional applications, the solution can be applied to various types of substrates such as textiles, wood, metals and alloys, and glass and silicium. In addition, surfaces such as alumina, silica, carbon ceramics and plastics (ABS) also make good substrates for the application.

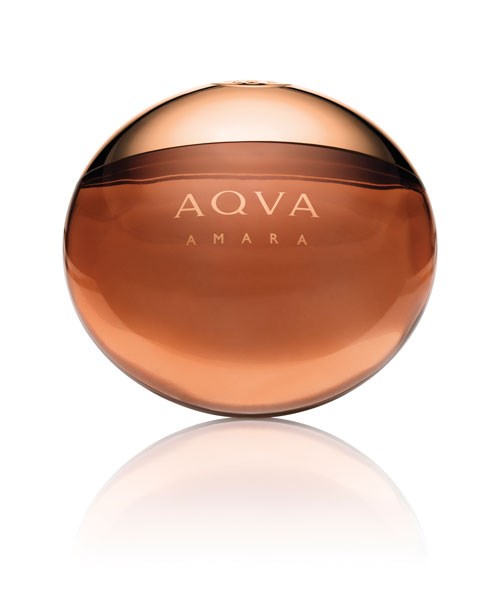

But one of the decorative aspects that sets Jet Metal’s applications apart for industries such as spirits and cosmetics is its metalization’s ability to achieve new effects such as transparency, shading or partial applications.

“It’s an innovation we’ve come up with to serve the marketing functions of the products,” Stremsdoerfer says. “It goes beyond the standard metalization of aluminum, chrome and gun metal. It adds new effects.”

The value proposition of Jet Metal’s process is that it is inline and has no breaks. The system that the company designs and installs goes through a base coat, the metalization process and then the topcoat.

Stremsdoerfer says that these systems can produce between around 10 million to 90 million metallized parts per year on a single line.

“It brings a high level of competitiveness, but it doesn’t have the electroplating baths or the traditional vacuum stress,” says Fourneron.

Given that the coatings industry faces stricter environmental controls on chemical waste and energy consumption, Fourneron points out that the Jet Metal process removes the need for sulfochromic preparation treatments, reduces the quantities of reagents used, minimizes the generation of wastewater and uses no VOCs.

“It really does create a synergy between the simplicity of painting techniques and the sophistication of metal plating coatings,” Stremsdoerfer says.

Simplicity of Painting

The Jet Metal technology was developed at one of France’s most prestigious engineering graduate schools, L´école centrale de Lyon, by someone very familiar to Stremsdoerfer: his father, Guy Stremsdoerfer, a professor at the university who now heads Jet Metal’s research and development.

While Professor Stremsdoerfer was studying how to ease the metalization of epoxy in the 1990s, he developed an innovative technology through the use of dynamic spraying. He received several European and U.S. patents on the process in 1997 under the title “Dynamic Chemical Plating.”

It wasn’t until 2007 that Samuel Stremsdoerfer took his father’s patents and technology and founded Jet Metal to industrialize the process. After Fourneron’s arrival, Jet Metal Technologies secured funding for its new coating technology from European venture capitalist firms Viveris, Schneider Electric Ventures, Naxicap Partners, Sofimac and Rhône Alpes Création, which helped Stremsdoerfer bring on additional staff including a marketing and research team.

“We were immediately seduced by the uniqueness and the potential of Jet Metal Technologies’ offer,” says Guillaume Dupont, investment partner at Schneider Electric Ventures. Other investors acted out of the knowledge that the impending European REACH regulations were going to put more environmental controls in place for the finishing industry.

Opportunities Await

“We were immediately impressed by the green tech concept of Jet Metal Technologies, giving the company a strong competitive advantage to be successful on its markets,” says M. Philippe Reynaud, investment manager at Viveris.

Fourneron says the company’s growth came about as a result of a perfect storm of opportunity. “Considering the economic situation and the environmental pressure on the surface treatment sector, Jet Metal Technologies comes with a very relevant answer: perfect timing.”

The company started with the installation of an industrial line for the glass industry, joined in 2009 by cosmetics and spirit packaging customers, and two years later penetrated the plastics industry with an industrial coating line installation.

Jet Metal broke into the international market in 2012 by placing offices in São Paulo, Brazil, opening a representative company in Japan and launching a high-capacity metalization line in Mexico. The company recently installed its 16th line in a coating facility in Portugal, but both Stremsdoerfer and Fourneron have spent a fair amount of time in the U.S., talking with cosmetics and spirits manufacturers and introducing their technology.

Design and Build

In addition to processes, the Jet Metal business model also includes the design and implementation of the appropriate industrial tools, project management, training, customer support and—of course—supplying the consumables for the process.

As for the functionality of the Jet Metal spray metalization process, Stremsdoerfer says that those questions are immediately tapped down, especially with having his father leading the R&D team. Conductivity and electromagnetic shielding are not an issue, he says, and the process allows any polymer material (such as ABS, polypropylene, SAN or polyimide as well as composites such as epoxy/carbon) to be conductive.

While claiming to offer hardness and antibacterial performance, Stremsdoerfer says that in order to reach some tribological properties and functional surfaces for composite coatings, the Jet Metal process also offers metallic coatings embedded with specific particles (such as TiO2, graphite, PTFE, MoS2, SiC) so that the composite coatings can have dry lubrication, hardness and traceability properties.

Growing Market

Stremsdoerfer knows that Jet Metal is targeting growth industries with its technology. The worldwide perfume market was around $28 billion in 2012, and industry experts expect it to grow to $45 billion by 2018.

“The market is set to benefit from the growing trend towards consumer urbanization, higher spending propensity and the heightened importance on personal appearance and grooming,” says Companies and Markets Research, a global aggregator of business information. “In addition, increased demand for youth-oriented, floral and exotic fragrances and celebrity perfumes will set the pace for rapid market expansion.”

Sales of spirits worldwide is also expected to grow modestly, having increased from 11 percent of overall alcohol sales in 2012 to just over 12 percent in 2013 (the latest year that figures were available from industry groups). The Spirits Business, an online publication dedicated to the industry, predicts that global spirits consumption will reach 3.37 billion cases by 2018, an increase of 290 million cases from 2012.

“The benefits are very obvious and real,” he says. “It is high capacity and minimal investment, and with less handling there is less rejected parts. It’s a very flexible technology that can work on many finishes.”

For more information on Jet Metal, please visit Jetmetal-tech.com or contact Sébastien Fourneron at s.fourneron@jetmetal-tech.com

RELATED CONTENT

-

Salt Spray Vs. Cyclic Corrosion Tests

Joseph Subda, ecoat specialist for Axalta Coating Systems, explains the difference between these two corrosion resistance tests.

-

A Protective Decorative Electrolytic Coloring Process for Aluminum

The main task of this work was to study the influence of the different parameters on the electrolytic coloring process for aluminum.

-

What is Electrocoating?

E-coat can produce uniform finishes with excellent coverage and outstanding corrosion resistance.