IHEA 2024 Annual Meeting

By: Lori Beckman

The Industrial Heating Equipment Association’s 2024 Annual Meeting will be held at the DeSoto Hotel in Savannah, Georgia, from March 20 – 22.

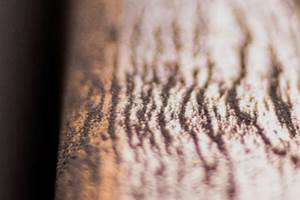

Interpon Helps Aluminum Coating Business with Sustainability

Edited by Lori Beckman

DFV is partnering with AkzoNobel Powder Coatings to keep the business out in front by using an Interpon powder coating technology that can make aluminum look like wood.

Company Announces Color of the Year

By: Lori Beckman

Axalta Coating Systems’ 2024 Global Automotive Color of the Year is Starry Night.

Ronatec Establishes Warehouse in Los Angeles

Edited by Lori Beckman

The facility has received approval from both the Department of Justice and the Drug Enforcement Administration.

Two Companies in Metal Processing and Coating Services Announce Rebrand

Edited by Lori Beckman

Metal Processing International and Oklahoma Custom Coating, two companies in the metal processing and coating services, have rebranded as ecoat.us, while maintaining same ownership.

Kolene Corp. Appoints New V.P. of Research and Development

Edited by Lori Beckman

Dr. Louis R. Pignotti joined Kolene in September 2012 as a senior research chemist, and progressed through the lab to chief chemist in January 2016 until his recent promotion.

Bodycote Expands Its Medical Market Reach with Acquisition

Edited by Lori Beckman

Bodycote has acquired Lake City Heat Treating, based in Warsaw, Indiana, and is a medical market provider of hot isostatic pressing (HIP) and vacuum heat treatment services.

Chemeon Celebrates 10 Years

Edited by Lori Beckman

Over the past decade, the company has been at the forefront of developing safer MIL-DTL qualified alternatives to the known carcinogen hexavalent chrome.

Axalta Receives International Sustainability and Carbon Certification Plus

Edited by Lori Beckman

This milestone further reinforces Axalta’s commitment to ensuring sustainability remains central to every part of its business.

Ceramic Abrasives Optimized for Long Life

Edited by Lori Beckman

Walter Surface Technologies’ Smart Resin technology, found in bonded abrasives, works to expose fresh ceramic grains at the optimal moment to achieve the most productive balance between sharpness and life in a metalworker’s given application.

Gema V.P. Retires

Edited by Lori Beckman

After almost 40 years of dedicated service, Chris Merritt has announced his retirement.

Powder Coating Formulation Combines Hardness and Flexibility

Edited by Scott Francis

IFS Coatings launches thermoplastic modified polyolefin powder coating that combines hardness and flexibility.