Dual-Shaft Mixers for High-Viscosity Dispersions and Suspensions

Edited by Lori Beckman

The Ross FDA-1500 has a maximum working capacity of 1,500 gallons and features a dish-bottom stainless steel mix vessel with a 50-psig dimpled heating/cooling jacket.

Weiler Abrasives Appoints New Chief Financial Officer

Edited by Lori Beckman

Mary Beth Martino will oversee the company’s global financial activities.

Sherwin-Williams 2024 Aerospace Coatings Calendar Winners

Edited by Lori Beckman

The annual program recognizes the exceptional craftsmanship and creativity of aircraft painters and designers who rely on Sherwin-Williams aerospace coatings.

#aerospace

Powder Coating Institute Accepting Applications for 2024 Scholarship

Edited by Lori Beckman

Designed to assist students studying in subject areas that can lead to a career in powder coating, the scholarship program awards funds in conjunction with PCI member company donations.

National Surface Finishing Day

By: Scott Francis

National Surface Finishing Day will be celebrated March 6, 2024. The annual event is a way to showcase the industry to local trade schools, businesses, officials and media, as well as to celebrate employees and staff.

#nsfd

Materials Group Celebrates 85 Years in Business

Edited by Lori Beckman

Wall Colmonoy, a global materials engineering group, celebrates its 85 years of business.

#management

NASF Now Accepting 2024 Scholarship Applications

Edited by Lori Beckman

College juniors, seniors and graduate students majoring in subjects related to surface science, now is your chance to apply for financial scholarships until Feb. 25.

Tri-Mer Announces New Process Engineer

Edited by Lori Beckman

Clayton Lynn has joined Tri-Mer Corp. as a process engineer where he will focus on the company’s legacy systems.

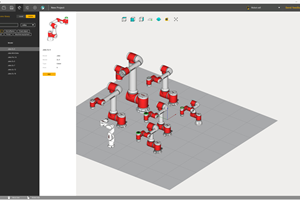

SprutCAM X Robot Integrates JAKA Cobots into its Library

Edited by Lori Beckman

SprutCAM Tech’s online library of robot components has been updated to include digital twins of the popular JAKA cobots.

PaintExpo 2024 Highlights Coating Processes of the Future

Edited by Lori Beckman

The industrial coating technology industry is increasingly focusing on sustainable and energy-efficient processes. This trend will be reflected at the PaintExpo 2024, April 2-9, 2024 in Karlsruhe, Germany.

#sustainability

AkzoNobel Powder Coatings Partners With CoatingAI

Edited by Katie Leesemann

The partnership aims to explore possibilities with sustainability, including the development of Flightpath.

#sustainability

PPG Opens Aerospace Application Support Center in France

Edited by Katie Leesemann

The aerospace application support center aims to provide regional customers with fast product delivery.