Sales Engineer Joins American Plating Power

Edited by Lori Beckman

Stocker has more than two decades of experience with an industrial power conversion product supplier in the sale and support of DC power supplies. In particular, he has a vast background in ecoat applications.

John Forlenzo Joins Hubbard-Hall

Edited by Lori Beckman

Photo Credit: Hubbard-Hall Hubbard-Hall welcomes John Forlenzo as supply chain manager.

MicroCare Appoints National Sales Manager

Edited by Lori Beckman

Photo Credit: MicroCare MicroCare, LLC has appointed Vince Libercci as national sales manager.

Electrolyte for Electroplating with Pure Platinum

Platuna PT enables the deposition of exceptionally thick, homogeneous and crack-free platinum layers, which are particularly convincing in various technical applications.

Proposed Coating Standard Will Support Corrosion Protection

Edited by Lori Beckman

The standard will establish performance requirements for electrodeposited nanostructured zinc-nickel coatings.

Companies Partner to Develop Sustainable Coil Coatings

Edited by Lori Beckman

Beckers has joined forces with ArcelorMittal to develop the first commercial paint formulations for electron-beam curing for the coil coating industry.

ALIT Technologies Transitions to a Joint-Stock Company

Edited by Lori Beckman

The company has transitioned from a S.r.l. to S.p.a., stating its goal is the issuance of bonds that will enable the expansion of the business.

New Technology for High-Definition Color Shifting

Edited by Lori Beckman

Kameleon FX Packs in five color combinations are easy to use and provide a clean color shift.

Polychem's 2024/2025 Powder Color Trend Collection

Edited by Lori Beckman

The color trend collection consists of 30 powder colors that represent trends.

Axalta Wins Two 2024 BIG Innovation Awards

Edited by Lori Beckman

Both the company’s Voltatex 7345 A ECO Wire Enamel and its Raptor Flameproof Coating have won the 2024 BIG Innovation Award presented by the Business Intelligence Group (BIG).

AkzoNobel Joins Program to Promote Sustainability

Edited by Lori Beckman

Seven broad consortia have been established as part of the government-funded “Perspectief” program, with AkzoNobel set to play a leading role in the SusInkCoat project.

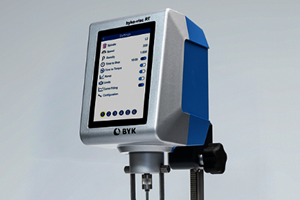

Self-Calibration Option for Rotational Viscometer

Edited by Lori Beckman

If added, the option will enable the instrument to self-calibrate throughout its life with a one-time purchase of this option.

#measurement-testing