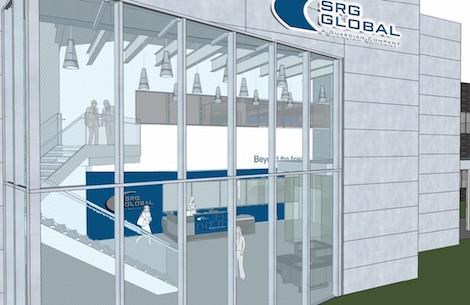

SRG Global Moving to World Headquarters in Troy

The new facility has more than 51,000-square-feet and will house the company’s support staff; it will be home to more than 250 employees.

#masking #pollutioncontrol

The new facility, located at 800 Stephenson Highway, encompasses more than 51,000-square-feet.

Featured Content

SRG Global is moving its world headquarters to a larger, modernized facility in Troy, Michigan.

As a leading global manufacturer, SRG Global is well-known as a Tier 1 interior and exterior trim supplier providing solutions that add both style and function for the automotive, commercial truck and household appliance industries.

The new facility, located at 800 Stephenson Highway, encompasses more than 51,000-square-feet (4,740-square-meters) and will house the company’s support staff for the global and North American businesses. The building will be home to more than 250 employees.

“Our new facility was created to inspire greater collaboration between our employees and customers, which will help drive more innovation into our designs and manufacturing solutions that meet the auto industry’s evolving needs,” said Dave Prater, President and CEO of SRG Global. “The building serves as a creative center focusing on our employees’ fulfillment and will be a place for them to foster ideas, share knowledge, inspire new technology developments and to develop their capabilities to create the greatest value.”

Since SRG Global was created, the company has opened and expanded six facilities around the globe. Of those six, one is an Advanced Development Center in Taylor, Michigan, which focuses on improving manufacturing processes and innovative solutions for subsystems and coatings.

While expanding global operations to serve automakers and other manufacturers around the world, Prater said the company is committed to keeping southeast Michigan its center of automotive excellence.

RELATED CONTENT

-

Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.

-

Stripping of Plated Finishes

The processes, chemicals and equipment, plus control and troubleshooting.

-

Blackening of Ferrous Metals

The reasons for installing an in-house cold blackening system are many and varied.