January 2018 ISSUE

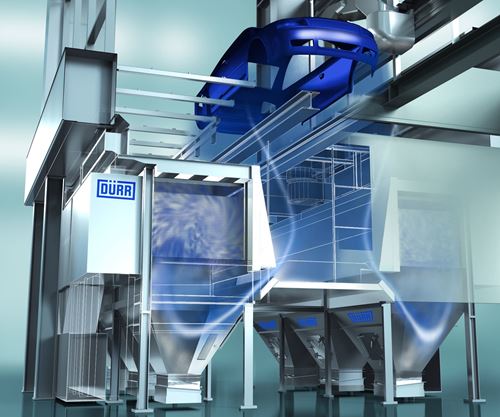

Dürr Named Core Supplier of Groupe PSA

With its multiple automotive brands — Peugeot, Citroën, DS Automobiles, Opel in Germany and Vauxhall in Great Britain — Groupe PSA has been a major customer of Durr’s for more than 20 years.

#automotive

FEATURES

ElectroplatingUyemura CEO Tony Revier Honored for Service, Contributions

Revier was honored as one of the the University of La Verne’s 125 Most Notable Graduates at a ceremony commemorating its 125th anniversary. The awards were presented by university President Devorah Lieberman to alumni based on four criteria.

Liquid Coating

BASF Coatings Supplies New Belarus Auto Plant for BelGee

The BelGee Belarusian site currently has capacity to produce 60,000 car bodies a year, with the option to expand.

Liquid Coating

CCAI Chapters Brighten Holidays for Local Charities

The Southern California, Central States and Wisconsin chapters conducted toy drives, and the Twin Cities and Central States chapters made cash donations to local charities.

Electroplating

Direct Metallization for Plating on Plastics

A new combination of copper immersion and autocatalytic copper-(I)-oxide deposition enables lower palladium concentrations in the activator bath, though the amount of copper deposited on the plastic surface can be up to ten times higher compared to its predecessor processes.

Liquid Coating

Dürr Named Core Supplier of Groupe PSA

With its multiple automotive brands — Peugeot, Citroën, DS Automobiles, Opel in Germany and Vauxhall in Great Britain — Groupe PSA has been a major customer of Durr’s for more than 20 years.

Electroplating

GE Aviation, Praxair Open Jet Engine Coatings Facility in Mississippi

PG Technologies is a joint venture between Praxair Surface Technologies Inc., a wholly owned subsidiary of Praxair Inc., and GE Aviation.

Electroplating

Leveling the Field in Nickel Plating

Profilometry helps determine the leveling characteristics of Watts nickel baths.

Liquid Coating

Mankiewicz Coatings Undergoes $30M Expansion at Charleston Facility

This expansion is quick, as the company only opened the initial $25 million, 90,000-square-foot facility in 2015.

Mechanical Finishing

Mastering Sanitary Stainless Steel Finishes

Here’s a primer on the types of finishes required for equipment used in sanitary applications.

Electroplating

Michigan Bill Targets PFAS

The $23.2 million allocation will provide testing, monitoring and technical assistance at more than a dozen sites across Michigan where PFAS have been found in groundwater.

New Mirror-Coating Technology Promises Dramatic Improvements in Telescopes

At UC Santa Cruz, an electrical engineer has teamed up with astronomers to improve telescope mirrors using thin-film technology from the electronics industry

Powder Coating

Powder Coated in the U.S.A.

A Florida manufacturer commits to making American products the old-fashioned way: by hand and from quality materials.

Liquid Coating

Scientists' High-Tech Paint Keeps Steel Beams from Melting

Callaghan Innovation’s team spent more than a year working with a paint firm to develop a fire-resistant coating known as intumescent.

Liquid Coating

Using 3D to Design a Paint Shop

Laser scanning helps optimize planning in brownfield expansion projects.

Liquid Coating

Vogel Paint's Powder Expansion Project Ahead of Schedule

The company says that Phase Three of a five-year, $29.3 million expansion plan for the powder coating operation located at its headquarters in Orange City, Iowa, will begin ahead of schedule.

Electroplating

Crack Formation during Electrodeposition and Post-deposition Aging of Thin Film Coatings - 6th Quarterly Report

This NASF-AESF Foundation research project report covers the sixth quarter of project work (April-June 2017) on this AESF Foundation Research project at the University of Houston. The objective of the work is to study fundamental and practical aspects of crack formation in electrodeposited thin films.

Electroplating

Electrodeposited Inconel and Stellite-like Coatings for Improved Corrosion Resistance in Biocombustors

This work deals with problems in the Third World – namely improving the safety and efficiency of cookstoves used by people around the world. A scalable and economic process is required to apply coatings on low-cost stainless steel substrates for enhanced high temperature corrosion resistance specifically targeted towards biomass combustion apparatus. Cost effective, scalable, and flexible electrodeposition-based coating of various alloys [Ni/Co]-Cr-[Mo/Fe] system, that are able to withstand high temperature corrosion and improve the functional lifetime of existing and next generation bio-combustors components is a desirable technological advancement. Within this context, a wide array of electrolytes and processing parameters were evaluated to develop an ideal alloy coating.

Michael Guckes: Finishing Industry’s Growth Slows

Matthew Kirchner: How Not to Quit Your Job

A Conversation with Jason Gatton, Pneu-Mech Systems

Tim Pennington: You Say You Want a Resolution?

Environmental Protection Considerations for a Rectifier

Understanding Liquid Film Defects

Improving Corrosion Protection

Options to Improve Passivate and Chromite Coatings

Solving Corrosion on Black-Dyed 7000 Series Alloy

Spray System Includes Electronically Integrated Proportionin

Pretreatment Leads to Water-break-free Plating Surfaces

Three-Zone Conveyor Oven Suited for Curing Coatings

Combination Wheels Boost Cutting, Grinding Productivity

A Super Defense Against Corrosion and Abrasion

Epoxy Primer, Topcoat Suited for Weathering-Susceptible Substrates

Solution Removes Metalworking Oils, Inhibits Rust

Triple-Angle Glossmeter Measures Variety of Surfaces

Combo System Provides Air for Both Safe Breathing and Paint Spray

Acrylic Coating Provides Hard Finish for Extruded-Aluminum Products

Water-based Shop Primer Inhibits Rust on Steel Surfaces