EPi Develops Inexpensive Corrosion-Resistant Oil

EPi’s new E-Tec 509 water displacement oil offers long-lasting corrosion resistance.

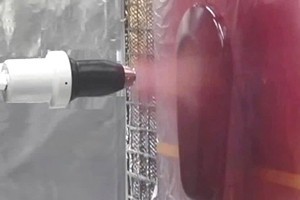

When to Use Air Spray Guns or Rotary Bell Atomizers for Robotics

For automated finishing, are air spray guns or rotary bell atomizers better? Mark Dion from Dürr Systems explains the pros and cons of both for robotic painting.

#basics #ask the expert

Applications Innovation Leads to Better Masking Solutions

When masking product failures are costing you money, it pays to work with an expert that can select or engineer the most efficient solution.

#masking

GFS' PIG Mat Streamlines Paint Booth Maintenance

GFS’ new PIG Grippy Mat protects streamlines paint booth floor care and facilitates higher-quality work.

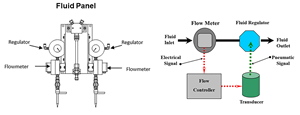

Pressure and Flow Control in Spray Guns and Rotary Atomizers

Tighter controls of paint flow and pressure may help finishers improve efficiency and profits.

#ask the expert

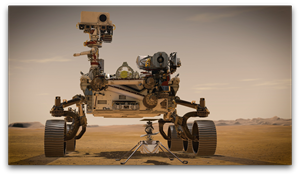

Special Coatings Support Mars Rover

The Mars 2020 Perseverence rover will rely on highly engineered surface treatments to protect it from the extreme temperatures of space and the harsh environment of Mars.

#masking

Three Diaphragm Pumps for Medium Paint Circulating Systems

Sames Kremlin diaphragm pumps feature compact design, quick flushing and resistant materials.

Giering Metal Finishing Completes Facility Expansion

The building, constructed in the late 1970s, was in sore need of a renovation for energy efficiency, Giering says.

#masking

Paint Booth of the Future Concept from Dürr

Dürr’s EcoProBooth has a modular box design, combines interior and exterior painting in one box and is designed for flexibility.

Carlisle Fluid Technologies Promotes Linda Hester

Hester is charged with promoting Carlisle’s brand recognition in the marketplace with emphasis on electronic media.