Materials and Coatings Development: From Bench Scale to Application

Materials research, and more specifically the development of novel coating methods, has been a central focus of Eltron R&D since the company’s inception over 25 years ago. Eltron has developed, synthesized and characterized materials ranging from nanoparticles to thin films and ceramics for a wide range of applications in the aerospace, semiconductor, energy and automotive industries.

#energy #aerospace #automotive

A Protective Decorative Electrolytic Coloring Process for Aluminum

The main task of this work was to study the influence of the different parameters on the electrolytic coloring process for aluminum.

#aerospace #surfin

2020 Vision: Vacuum Coatings

Across all industries – medical device, automotive, electronics, military and aerospace ‑ electronic components are becoming smaller in size, but more complex in application capabilities.

#medical #military #electronics

Development of Ni-Based High Wear Resistance Composite Coatings

Hard chromium has been used in automotive, aerospace, mining and general engineering industries due to its excellent wear resistance and low coefficient of friction.

#surfin #aerospace #automotive

Finishing Chemical Business Could Hit $8B by 2015

A new report out suggests that sales of metal finishing chemicals could hit $8 billion globally by 2015, driven by electronics and electrical, motor vehicle equipment and the aerospace industries.

#electronics #aerospace #automotive

Becoming an Approved Aerospace Anodize Supplier

Fabrication of aerospace structure requires rigorous standards due to the high cost of rework and the severe consequences of in-flight failure. To become a supplier for aerospace anodize, an approval process which is not readily understood must be followed.

#aerospace

Better Peening Shouldn’t Be a Shot in the Dark

Almost any pilot will tell you that when it comes to airplane parts like wings or engine blades, failure is unacceptable. That’s why more aerospace companies have sought to reduce the possibility of metal fatigue in such critical parts, and why some manufacturers of those pieces use a technique called shot peening.

#aerospace

Becoming an Aerospace Anodizing Supplier

Fabrication of aerospace structure requires rigorous standards due to the high cost of rework and the severe consequences of in-flight failure. To become a supplier for aerospace anodize, an approval process which is not readily understood must be followed.

#aerospace

Improving Aerospace Engines with Advanced Materials

Advanced ceramics and high performance superalloys are playing an important role in improving aerospace engines as aerospace manufacturers look for high-temperature materials that increase performance, improve fuel efficiency and satisfy safety standards, while at the same time lowering manufacturing costs.

#aerospace

Overview: Aerospace Anodize Finishes

The following anodizing process overviews are provided as a means of introduction to aerospace anodizing

#aerospace

Advice & Council: Aluminum

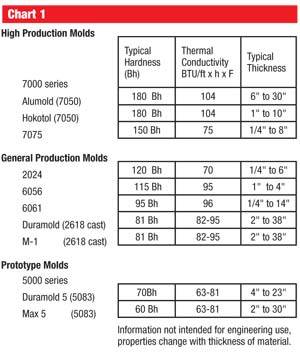

Frank Altmayer offers this quick primer on the aluminum materials commonly found in aerospace manufacturing.

#aerospace

Back in Black: Birchwood Casey's black oxide

Black anodize finishes have long been favored for their thick, hard coating properties. It is also these very same characteristics that often make the anodizing unusable for many military and aerospace applications.

#military #aerospace

Blasting Off!

Three aerospace job shops weigh in on why being everything to everyone may not be the best approach for growth

#aerospace

Superior Spraying

Gun upgrade boosts paint productivity for aerospace finisher

#masking #curing #aerospace

A Conversation With ... Tom Captain

Vice Chairman, Global and U.S. Aerospace and Defense Industry Practice, Deloitte Consulting

#military #aerospace

Flying High

UV-curable powders set to make inroads in military, aerospace applications

#military #aerospace

Process- Focused

Training, industry certification boost aerospace plater

#education #aerospace #workforce development

New Finishing Technologies Taking Off

Trends in coating and finishing for aerospace and defense

#military #aerospace #pollution control

Custom Masking Helps Hixson Soar

Boosts productivity at aerospace finishing shop

#masking #aerospace

Trends in Making Ultrasonic Frequency Work for You

Well-designed ultrasonic cleaning systems have a proven track record of delivering gentle yet thorough parts-cleaning without regulated solvents to industries as diverse as aerospace, electronics, automotive and coating.

#electronics #aerospace #automotive