Vapor Technologies Offers Hybrid PVD Coater

FABTECH 2020: Vapor Technologies offers hybrid PVD coaters which can be used for cathodic arc, sputtering or both.

#vacuum-vapor

Vapor Degreasing: A Fresh Look at an Old Process

Solvent-based cleaning using a vapor degreaser is seeing a resurgence as an alternative cleaning method due to the development of environmentally safe cleaning fluids.

#vacuum-vapor

The Right Solvent Creates the Cleanest Parts

Cox Manufacturing Co. has worked with Kyzen Corp. since it implemented its vacuum vapor degreaser to find just the right chemical solvent to clean its customers’ parts to their specifications and beyond.

#vacuum-vapor

Hauzer Launches Flexible PVD Coating Machine

Flexicoat 1250, the new PVD coating machine from Hauzer, has an increased loading capacity, seven cathode positions and eight plate positions.

#vacuum-vapor

Advanced Finishing Technologies Pilots Closed-Loop Vacuum Evaporation System

Custom-designed chrome reclamation system minimizes water and chemical consumption, and waste effluent.

#vacuum-vapor

Recyclable VCI Moisture-Barrier Paper Surpasses Biobased Content Requirements

Cortec’s EcoShield VpCI-144 moisture barrier VCI (vapor corrosion inhibitor) paper contains 69% USDA certified biobased content.

#vacuum-vapor

A Lustrous Example of Expanding a Plating Operation

Ohio’s Lustrous Metal Coatings Pins Growth on Acquiring Other Manufacturing Operations

#vacuum-vapor

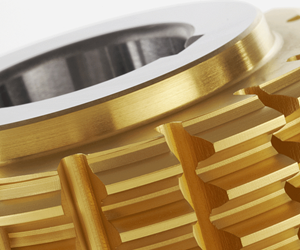

Hybrid Coatings on Centrifugal Fans in Steel Plants

A centrifugal fan in a steel plant is often exposed to abrasive dust, which results in material loss and a shortage of running time for the fan.

#vacuum-vapor

Sweden's Impact Coatings Developing Hyundai Fuel Cell Coatings

Development agreement of coating technology for metal bipolar plates, a key component of hydrogen fuel cell electric vehicles.

#vacuum-vapor #automotive

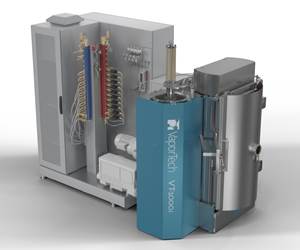

VaporTech Customizes CVD and PVD Coating Colors

PVD and DLC coating machines are simple to integrate into manufacturing processes.

#vacuum-vapor

Industrial Cleaning Furnaces Remove Pollutants

Controlled pyrolysis process converts organic-based materials into a carbon-based smoke which passes through a 1,500ºF afterburner exiting the exhaust stack as odorless water vapor and carbon dioxide.

#pollution control #vacuum-vapor

Voestalpine Eifeler Coatings Opens PVD Facility in Tennessee

This opening follows the company’s opening of their coatings facility in Walnut, California, in June. The company is headquartered in Düsseldorf, Germany.

#vacuum-vapor

Choosing the Right Vapor Degreasing Method

Venesia Hurtubise with MicroCare says experience and expertise are helpful in optimizing and developing cleaning cycles that will best suit a specific job.

#ask the expert #vacuum-vapor

When to Perform Vacuum Impregnation on Parts

Andy Marin from Godfrey and Wing says the general rule is that vacuum impregnation should be done before any surface finishes.

#vacuum-vapor #basics

Vapor Degreasing Process Uses TCE Replacement to Eliminate Hazardous Waste

A solid relationship with a solvent manufacturer has aided Electro-Spec Inc. with the implementation of a trichloroethylene replacement material in its vacuum degreasing unit to clean a customer’s micromachined parts more efficiently.

#vacuum-vapor

Winona Coatings Rolls Along With PVD, Powder Coatings

The physical vapor deposition (PVD) coating provides the reliability of a painted wheel but the look of chrome and saves 1-2 pounds of weight on each wheel.

#vacuum-vapor

Grieve Oven for Composite Parts in Vacuum Bags

Workspace dimensions are 42-inches wide by 40-inches deep by 50-inches high with a 4200 CFM, 3-horsepower recirculating blower provides universal airflow to the workload.

#vacuum-vapor

Smaller Systems Designed for In-House PVD Coating

Vapor Technologies has introduced a line of smaller, lower-cost physical vapor deposition (PVD) coating machines designed to allow manufacturers to bring PVD operations in house and coat parts more cost-effectively.

#vacuum-vapor

The Value of PVD Coatings for Medical Devices

Applying a PVD coating to medical devices can offer both aesthetic and functional advantages. Here are answers to some frequently asked questions.

#medical #vacuum-vapor

In-House PVD Coating System Saves Time, Costs

VaporTech’s VT-3000i coating system is designed to deposit materials using physical vapor deposition (PVD) or plasma-enhanced chemical vapor deposition (PE-CVD), as well as coat temperature-sensitive substrates using low-temperature arc vapor deposition technology (LTAVD).

#vacuum-vapor