How to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

#ask the expert #basics

Prevent Plating Problems with Critical Inspections

Tanks and their contents should be regularly inspected visually and analytically. When a quality issue arises, it is important to quickly pinpoint where the main problem is by checking which parameter is out of line.

#ask the expert #basics

Powder Coatings vs Energy-Cure Coatings

Examining the basic differences between powder coatings and energy-cure coatings can help answer the question of whether or not one of these technologies might be appropriate for a specific application.

#ask the expert #basics

Curing Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

#basics #curing

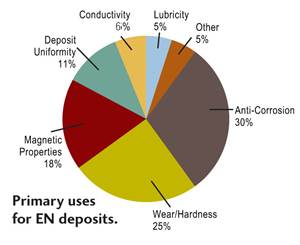

An Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

#basics

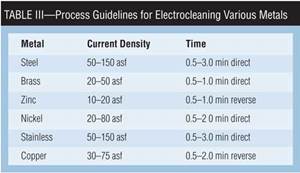

Preparation for Electroplating

What you should know about cleaning and electrocleaning.

#basics

Alkaline Cleaning Guide

Gregg Sanko, Senior Chemist, Oakite Products, Inc. provides an overview of the alkaline cleaning process.

#basics

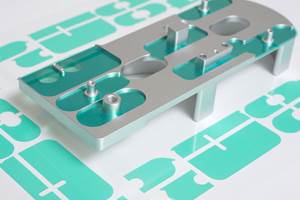

Can You Afford to Not Use Custom Masking?

Are you weighing the costs of a custom masking solution vs. an off-the-shelf solution? Christy Schulthess of Custom Fabricating & Supplies discusses the overall savings that can be realized with custom masking.

#ask the expert #masking #basics

A Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

#basics

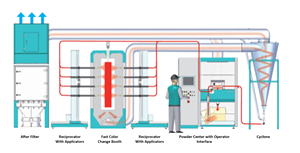

Choosing the Right Powder Booth Technology

Is your powder coating operation experiencing an increasing number of color change requirements? Nicolas Gervaise of Carlisle Fluid Technologies discusses fast color change single booth configurations for powder coating.

#ask the expert #basics

Understanding PEO Coatings

Using high-speed cameras and back side illumination (BSI) sensor technology to analyze plasma electrolytic oxidation.

#basics

Conveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

#basics

Understanding and Managing White Spots on Anodized Aluminum

Having trouble with spotting defects when anodizing? Taj Patel of Techevon LLC offers a helpful overview of the various causes of white spots and potential solutions.

#basics #management #ask the expert

How to Maximize Nickel Plating Performance

The advantages of boric acid-free nickel plating include allowing manufacturers who utilize nickel plating to keep up the ever-changing regulatory policies and support sustainability efforts.

#sustainability #regulation #basics

Installing an Ecoat Line

Thinking of investing in electrocoating capabilities? George Lovell, coatings plant manager for Lippert, discusses considerations you should keep in mind as you add your ecoat line.

#ask the expert #basics

How to Build a Powder Coating Brand

Maui Powder Works, a 2022 Products Finishing Top Shop, shares the story behind how it grew from an island job shop to a recognized voice in the finishing community.

#basics #Top Shops

Top Reasons to Switch to a Better Cleaning Fluid

Venesia Hurtubise from MicroCare says switching to the new modern cleaning fluids will have a positive impact on your cleaning process.

#ask the expert #basics

Anodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

#aerospace #basics

Zinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment

#pollution control #basics