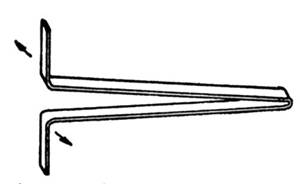

How to Increase Line Density

Q. Our finishing shop applies both liquid and powder applications, as well as some plating, too. How can we increase our racking line density by adding more parts per foot? Racking expert Scott Rempala has the answer.

#basics #racking

How to Implement Ambient Temperature Cleaning

Q. How can we find an ambient temperature spray cleaner to implement for our five-stage pretreatment line used prior to powder coating? Cleaning expert David Peterson has the answer.

#basics

How to Identify Substrate or Paint Defect

Q. Over the past several years we have had a coating defect anomaly randomly show up on painted parts...Cleaning expert David S. Peterson takes a close look at cleaning processes to identify the root cause.

#basics

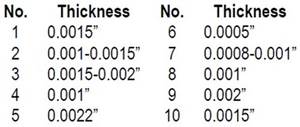

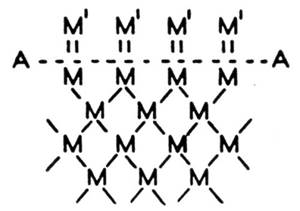

AES Research Project 3, Adhesion of Electrodeposits, Part 4, Commentary on Measurement

This is Part 4 of a four-part article consisting of the full report of AES Research Project #3, Adhesion of Electrodeposits, done at the University of Michigan in the mid-1940s, following the end of World War II. It contains a commentary by industry people on the published methods for measuring adhesion.

#basics

AES Research Project 3, Adhesion of Electrodeposits, Part 3, Publications Review on Measurement

This is Part 3 of a four-part article consisting of the full report of AES Research Project #3, Adhesion of Electrodeposits, done at the University of Michigan in the mid-1940s, following the end of World War II. It reviews the published methods for measuring adhesion.

#basics

AES Research Project 3, Adhesion of Electrodeposits, Part 2, General Considerations

This is Part 2 of a four-part article consisting of the full report of AES Research Project #3, Adhesion of Electrodeposits, done at the University of Michigan in the mid-1940s, following the end of World War II. It outlines the general concepts involved on plate adhesion.

#basics

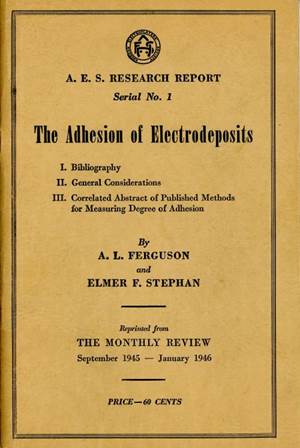

AES Research Project 3, Adhesion of Electrodeposits, Part 1, Bibliography

This is Part 1 of a four-part article consisting of the full report of AES Research Project #3, Adhesion of Electrodeposits, done at the University of Michigan in the mid-1940s, following the end of World War II. It consists of the complete bibliography compiled during the project.

#basics

AES Research Project 3, Adhesion of Electrodeposits, Prologue

This is the prologue for a four-part article consisting of the full report of AES Research Project #3, Adhesion of Electrodeposits, done at the University of Michigan in the mid-1940s, following the end of World War II.

#basics

How to Choose the Right Paint Booth Filters

Q. Our shop spends a lot of time on maintenance for our paint booth filters. How can we improve our operation, and what should we be looking at for filtration options?

#basics

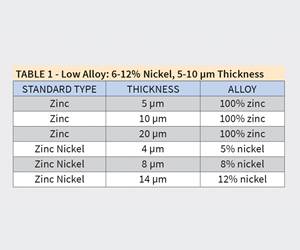

How to Use XRF Testing Instruments to Accurately Measure Zinc Nickel

Q. What are the XRF testing requirements for plating zinc nickel alloy?

#basics

How to Eliminate White Chalky Substance from Vibratory Finished Parts

Q. We are getting a white chalky substance left on our aluminum parts after vibratory finishing and it affects the coating adhesion. How do we eliminate this problem?

#basics

Crack Formation during Electrodeposition and Post-deposition Aging of Thin Film Coatings - 5th Quarterly Report

This NASF-AESF Foundation research project report covers the fifth quarter of project work (January-March) on this AESF Foundation Research project at the University of Houston. The objective of the work is to study fundamental and practical aspects of crack formation in electrodeposited thin films.

#nasf #basics

How to Make Automotive Paint Shops More Sustainable

Q. Our paint shop is the place of highest energy consumption and highest VOC and CO2 emissions in the car manufacturing process. What measures can be taken to reduce them?

#measurement-testing #energy #automotive

How to Use Pretreatment to Improve Salt Spray Hours

Q. Our goal is to have our gas regulators pass ASTM B117 for 500 hours. We use an epoxy powder coat; parts are treated with zinc phosphate first, then powder coated. We are seeing the internal parts of the castings rusting prematurely. Which spec could I call out to increase corrosion protection, MIL-DTL-16232G Type Z, class? Or TT-C-490, Type I?

#basics #regulation

How to Identify and Maintain Ecoat Bacteria

Q. Our electrocoat supplier tested our system for bacteria and reported that we are positive for bacteria. What kind of bacteria are found in ecoat systems and where can they come from? How can this affect the operation of the system?

#basics

How to Use Selective or Brush Plating for Zinc-Nickel

Q. Is there an approved process to repair damaged or defective zinc-nickel on aircraft components?

#basics

How to Strip Zinc Phosphate Without Using Chromic Acid

Q. I want to remove zinc phosphate from hardware parts after cold heading. Typically to remove zinc phosphate, I would soak in chromic acid at a high temperature, but this is not a viable or safe method for bulk treatment. Can I just hit the parts with a higher concentration of potassium hydroxide at a higher temperature to remove the zinc phosphate?

#basics

How to Solve Filiform Corrosion Issues When Spraying on Aluminum Alloy

Q. We are spraying on an aluminum alloy and are having problems with aluminum filiform corrosion. Can you help me understand what is causing this?

#basics

How to Increase Throughput with Racking

Q. How can I increase the throughput of my finishing line through proper racking protocols?

#basics #racking

How to Reduce Heat Gain in a Building with a Powder Coating Operation

Q. We get an enormous amount of heat in our building when our powder system is running. In the summer months, the building is almost unbearable. How can we reduce heat gain from our equipment?

#basics