Electro-codeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 2nd Quarterly Research Report

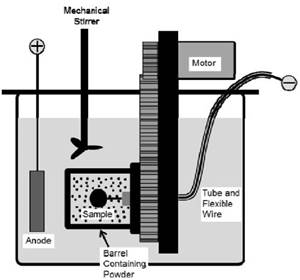

In this quarter, focus was on planned research on the effect of current density and powder density on CrAlY(Ta) particle incorporation in electro-codeposited Ni-CrAlY(Ta) composite coatings.

#research

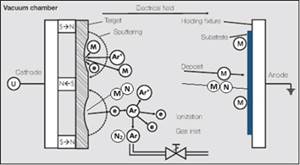

Advances in Decorative PVD Chromium Coatings for Polymer Substrates

This article reviews a two-layer, selective coating process which incorporates a specially developed UV-cured paint base coating with a sub-micron thick PVD chromium top coating. It illustrates the coating’s testing protocols of automotive manufacturers and the necessities of controlling the stresses within the coating matrix.

#research #vacuum-vapor #surfin

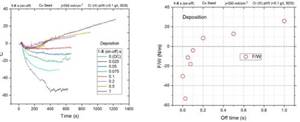

Crack Formation during Electrodeposition and Post-deposition Aging of Thin Film Coatings - 9th & 10th Quarterly Report

This NASF-AESF Foundation research project report covers the ninth and tenth quarters of project work (January-June 2018) on this AESF Foundation Research project at the University of Houston. The work continued towards identifying the effective pulse deposition approach to control and mitigate the stress state of chromium thin films and also involved a comprehensive study of palladium stress evolution during electrodeposition and strategies to mitigate its magnitude.

#research #nasf

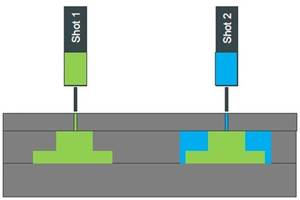

Is it Time to Revisit your Plastic Metallization Process?

The plating on plastics (POP) market has evolved to include an ever-broader range of substrates, huge increases in selective plating demand, using tools such as two-shot molding and laser ablation.

#research #economics #surfin

Electro-codeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 3rd Quarterly Research Report

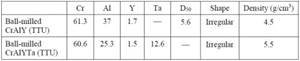

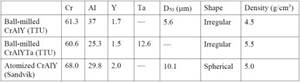

This NASF-AESF Foundation research project report covers the third quarter of project work (July-September 2018) on this AESF Foundation Research project at the Tennessee Technological University. The objective of the work is to study and optimize the MCrAlY electro-codeposition process to improve the coating oxidation/corrosion performance. In this quarter, studies continued on the effect of current density on CrAlY particle incorporation in electro-codeposited Ni-CrAlY composite coatings, focusing on the current density range of 20 to 60 mA/cm2.

#research #nasf

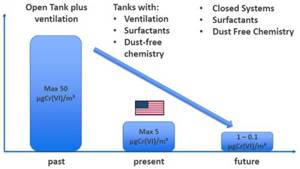

Technology Advancements for Select Key Hard Chromium Applications

This paper presents recent industry specific hard chromium technology advancements such as meeting the needs of the automotive and hydraulic industries. Examples for additional improvement potential are shown to simplify the operation and make hard chromium plating even more reliable in its specific needs for a wide range of industries served.

#research #surfin #automotive

Innovative, Hybrid Functional Coatings for Aluminum and Titanium Substrates

This paper describes a low cost alternative coating technology for light metals that electrodeposits an engineered thin-film coating which bonds tightly to the substrate and provides excellent corrosion and wear resistance along with superior electrical and thermal performance. As a new process, this technology offers a stable, low-cost option to manufacturers and applicators seeking to improve and extend their use of light metal substrates.

#research #surfin

Cyanide Destruction: A New Look at an Age-Old Problem

Cyanide in mining and industrial wastewaters has been around from the beginning, including electroplating processes. This presentation reviews a number of current processes, and in particular, offers new technologies for improvement in cyanide destruction by the most common process, using sodium hypochlorite.

#research #pollution control #surfin

Electro-codeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 4th Quarterly Research Report

This NASF-AESF Foundation research project report covers the fourth quarter of project work (October-December 2018) on this AESF Foundation Research project at the Tennessee Technological University.

#research #nasf

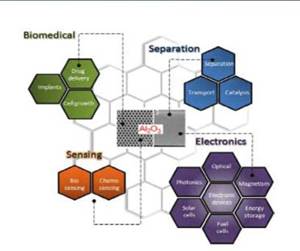

Nanoporous Anodic Oxides: Fabrication, Applications, Sensing and Biosensing

Numerous metals are subjected to anodic oxidation. As a result, one can obtain amorphous barrier-type oxides, crystalline barrier-type oxides or amorphous nanoporous oxides. This paper provides details of sensing techniques and recent advances in the development of NAA-based sensing and biosensing technologies.

#surfin #research