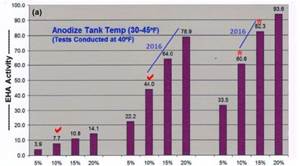

New Selective Brush / Cell Anodizing Technology Using Sulfuric / Organic Mixed Electrolytes for Dimensional Restoration of Difficult Alloys

This paper presents new innovative problem-solving technology for Type I, II and III selective brush and repair cell anodizing. Discussions include: (1) anodizing difficult alloys (2000/7000 series) without burning; (2) unique amino complex organic acid protection of the aluminum/anodize surface during processing and (3) high speed anodizing in selective cell operations, including heavy thickness anodize repair procedures.

#research #surfin

NASF Seeks Nomination for Industry Awards

The NASF will recognize a number of well-deserving individuals in several different awards categories. Nominations are due by March 30.

#surfin #nasf

Electroless Nickel Coatings: Appearance, Gloss and Surface Morphology

For decorative coatings, appearance is the essential purpose for application, but also for functional surface finishes it becomes increasingly relevant as an added value on top of specified technical requirements. Appearance is affected by spectrum and intensity of incident light, roughness and morphology of the coating surface, optical properties of the coating material, eventual superficial oxide films, and individual perception. The predominant factor is surface roughness, which in turn depends on base material roughness, quality of substrate pretreatment, and nucleation and growth kinetics of the electroless nickel (EN) deposit. Interdependency of gloss measurements with roughness measurements and with chemical composition of coatings was investigated for new generation mid-P EN processes and compared to traditional ones.

#surfin #research

Nanostructures by Anodization of Alumina in Phosphoric Acid at Low Potential

Anodic aluminum oxide (AAO) has been investigated, in terms of influence of the process time, anodizing potential and methanol addition on the structural features of porous anodic alumina formed in 0.1M H3PO4 solution by two-step self-organized anodizing for potentials ranging from 100-150 V. The structural features of the porous structures, including pore diameter and interpore distance, were evaluated from FE-SEM top-view images for samples anodized in the presence and absence of methanol.

#research #surfin

2018 Hall of Fame Inductees

Abner Brenner, Dr. George E.F. Brewer, Daniel Brockman, Richard Crain, Pieter de Lange, Ronald Duncan, Dr. Erwin Gemmer, David Marsh and Blair Vandivier were picked by an independent panel of industry executives.

#finishinghalloffame #surfin

Additive Manufacturing and Surface Finishing - The 53rd William Blum Lecture

This presentation is the 53rd William Blum Lecture, presented at SUR/FIN 2016 in Las Vegas, Nevada on June 6, 2016. In this lecture, Dr. Melissa Klingenberg discusses additive manufacturing; that is, any manufacturing process capable of making 3D objects from a digital model, or building-up 3D features onto an existing object, layer-by-layer. Cold spray, thermal spray, electroforming, structural plating and gaseous carbonyl deposition are covered.

#research #additive-manufacturing #surfin

Nickel: Science, Health and the Future - The 52nd William Blum Lecture

This presentation is the 52nd William Blum Lecture, presented at SUR/FIN 2015 in Rosemont, Illinois on June 8, 2015. In this lecture, Dr. Hudson Bates discusses the nickel research in his group at the Nickel Producers Environmental Research Association (NiPERA), which impact occupational health and environmental issues for nickel. This includes nano-particulates, toxicity of mixtures, ambient air effects, and providing good science in regulatory matters.

#surfin #research #medical

Surface Finishing Sustainability: Technology Pathways - The 51st William Blum Lecture

This presentation is the 51st William Blum Lecture, presented at SUR/FIN 2014 in Cleveland, Ohio on June 9, 2014. In this lecture, Dr. Yinlun Huang discusses the critical issue of sustainability in manufacturing with the primary focus on the surface finishing industry, and the technology directed toward addressing the issue.

#research #surfin #sustainability

Decorative Electroplating: Theory to Explain Rapid Corrosion Due to Calcium Chloride ‘Russian Mud’ - The 48th William Blum Lecture

This presentation is the 48th William Blum Lecture, presented at SUR/FIN 2010 in Grand Rapids, Michigan on June 14, 2010. In this lecture, Dr. Donald Snyder describes the phenomena behind a new challenge to decorative Cu-Ni-Cr plating, catastrophic corrosion failures involving the use of calcium chloride on Russian highways

#research #surfin

Electrodeposited Inconel and Stellite-like Coatings for Improved Corrosion Resistance in Biocombustors

This work deals with problems in the Third World – namely improving the safety and efficiency of cookstoves used by people around the world. A scalable and economic process is required to apply coatings on low-cost stainless steel substrates for enhanced high temperature corrosion resistance specifically targeted towards biomass combustion apparatus. Cost effective, scalable, and flexible electrodeposition-based coating of various alloys [Ni/Co]-Cr-[Mo/Fe] system, that are able to withstand high temperature corrosion and improve the functional lifetime of existing and next generation bio-combustors components is a desirable technological advancement. Within this context, a wide array of electrolytes and processing parameters were evaluated to develop an ideal alloy coating.

#research #surfin

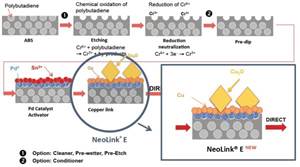

Direct Metallization for Plating on Plastics

A new combination of copper immersion and autocatalytic copper-(I)-oxide deposition enables lower palladium concentrations in the activator bath, though the amount of copper deposited on the plastic surface can be up to ten times higher compared to its predecessor processes.

#surfin #research

Defects in Hard Chromium Deposits Part II: Detection, Prevention and Repair

Most defects in various hard chromium deposits arise from defects in the basis metal. These defects may be in the original metal surface or may be caused by preplate finishing. Homogeneous hard chromium deposits can be produced only by eliminating these defects. The final segment of this article describes visual and provocative methods of detecting defects. Also discussed are prevention techniques and repair operations.

#research #surfin

Defects in Hard Chromium Deposits Part I: Causes and Cures

The causes of and remedies for defects in hard chromium deposits are explored in the first of this two-part P&SF article from 1984. Photomicrographs and SEM (scanning electron microscope) photographs will illustrate that most defects in various hard chromium deposits arise from defects in the basis metal. These defects may be in the original metal surface or may be caused by preplate finishing. Homogeneous hard chromium deposits can be produced only by eliminating these defects. Practical suggestions and procedures will be given.

#research #surfin

Can Electroplated Fe-C be an Environmentally Friendly Alternative to Hard Chromium and DLC Coatings?

Electroplated FeC is an efficient surface treatment based on non-aggressive chemicals with a deposition rate of ~20 μm/h at a process temperature of 50°C. The FeC coating is carbide-free and temperature stable up to ~250°C with a hardness of 750 HV, which is comparable to frequently applied hardened steels. The FeC coating has reasonable friction properties and have high affinity towards lubricants because of incorporated amorphous carbon. Hence, for certain applications, the FeC coating might be an interesting wear-protective alternative to hard chromium and to PVD-deposited low-friction diamond-like carbon coatings (DLC’s), which are rather difficult and costly to deposit on larger items.

#research #surfin #vacuum-vapor

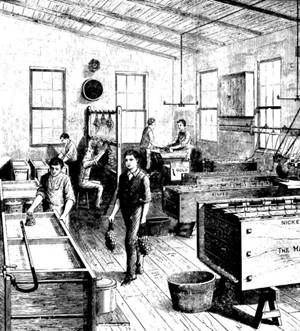

Faraday's Children (and Nickel): The 40th William Blum Lecture

This article is a republication of the 40th William Blum Lecture, presented at the 86th AESF Annual Convention in Detroit, Michigan on June 21, 1999. In this lecture, Dr. George DiBari describes the search for the ideal nickel anode material and the outlook for survival of nickel plating at the end of the 20th century.

#surfin #basics

Fame for Those in Liquid and Powder

Since 2014, Products Finishing has honored those in the electroplating field by inducting them into its Hall of Fame. For 2018, we want to open it up to all types of finishing sectors.

#finishinghalloffame #surfin

The Systems View in Automotive Finishes: Essential, but Overlooked - The 38th William Blum Lecture

This article is a re-publication of the 38th William Blum Lecture, presented at the 84th AES Annual Convention in Detroit, Michigan on June 23, 1997. This lecture reviews a number of works in automotive finishing R&D in which understanding of the overall system was absolutely essential to success, from classical nickel-chromium plating to work in vacuum/electroplated hybrids for plated plastics, electrogalvanized zinc and hard chromium in stamping dies.

#basics #surfin #vacuum-vapor

NASF Report: August 2017

The NASF Bright Design Challenge took on a new look and feel this spring with the theme “Advancing Brand Identity for the Next Automotive Era.” The competition included 12 graduate students who devoted their semester to envisioning the role of metal finishing in automotive designs for 2025 and 2050 vehicle models.

#automotive #nasf #surfin

40-Under-40: Class of 2017

Chicago’s Amanda Beach leads the 2017 Products Finishing list recognizing tomorrow’s leaders in the finishing industry.

#workforce development #40-under-40 #surfin

Looking Back - The 24th William Blum Lecture

This article is a re-publication of the 24th William Blum Lecture, presented at the 70th AES Annual Convention in Indianapolis, Indiana, on June 27, 1983. A career retrospective of Mr. Pearlstein’s works, the lecture covered work on electroless plating, chromate conversion coatings, double-layer phenomena and dealing with cyanide wastes.

#surfin