Is it Time to Revisit your Plastic Metallization Process?

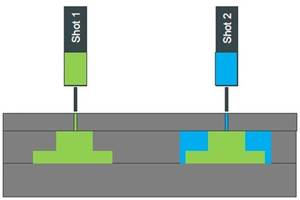

The plating on plastics (POP) market has evolved to include an ever-broader range of substrates, huge increases in selective plating demand, using tools such as two-shot molding and laser ablation.

#research #economics #surfin

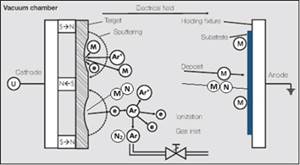

Advances in Decorative PVD Chromium Coatings for Polymer Substrates

This article reviews a two-layer, selective coating process which incorporates a specially developed UV-cured paint base coating with a sub-micron thick PVD chromium top coating. It illustrates the coating’s testing protocols of automotive manufacturers and the necessities of controlling the stresses within the coating matrix.

#research #vacuum-vapor #surfin

A Conversation with Cheryl Clark, NASF Director of Events

The National Association for Surface Finishing’s Sur/Fin conference saw record crowds this past June, and much of the credit goes to the person the NASF has to put on the event, Cheryl Clark.

#surfin #nasf

Innovative Applications of Electroplating and PVD for New Material Solutions - The 54th William Blum Lecture

The following is Dr. Per Møller’s William Blum Memorial Lecture at SUR/FIN 2018, in Cleveland, Ohio on June 4, 2018, with commentary by NASF Technical Editor James H. Lindsay. It covers a variety of projects involved with surface finishing applications, including sustainable energy. Due to Dr. Møller’s serious illness, he was unable to make the journey to SUR/FIN. In his stead, his longtime professional colleague, Dr. Lars Pleth Nielsen, of the Danish Technological Institute (DTI), presented the lecture.

#research #surfin #vacuum-vapor

Dr. James Lindsay Receives NASF Presidential Award

Others receive honors at NASF Sur/Fin Conference

#nasf #surfin

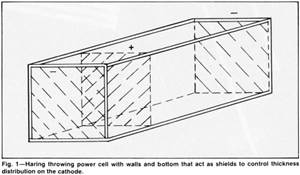

III. The Effects of Shields and Baffles on the Distribution of Functional Chromium Electrodeposits

This is the third of three combined papers that received the AESF Gold Medal Award for Best Paper published in Plating & Surface Finishing in 1989. Insulating shields and baffles redirect the flow of current and affect the thickness distribution of chromium and other electrodeposits. Many examples of these useful devices for improving the uniformity of chromium deposits are described.

#research #surfin

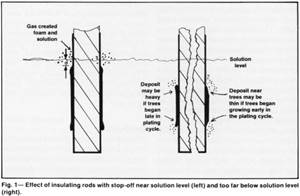

II. The Effects of Stopoffs and Thieves on the Distribution of Functional Chromium Electrodeposits

This is the second of three combined papers that received the AESF Gold Medal Award for Best Paper published in Plating & Surface Finishing in 1989. Stop-offs, thieves and guards are used to change the pattern of current flow and improve metal distribution. The effects may be planned or may occur unexpectedly, producing undesirable results.

#research #surfin

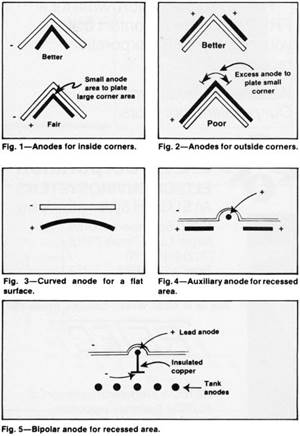

I. Rack and Anode Effects on the Distribution of Functional Chromium Electrodeposits

This is the first of three combined papers that received the AESF Gold Medal Award for Best Paper published in Plating & Surface Finishing in 1989. Procedures for improving functional chromium thickness distribution begin with this paper that advocates useful rack designs and anode configurations.

#research #surfin

30-in-30 from the 2018 Products Finishing Management Stage

Download the “30-In-30” that delivered 30 great tips and ideas from Top Shop operators on ways to improve efficiencies, in a fast-paced 30-minute presentation.

#Top Shops #surfin #management

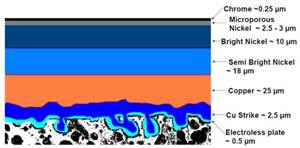

Acid Copper Technologies for Plating on Plastics

Automotive OEM performance requirements continue to increase which presents increased challenges to the supply chain to provide acceptable parts. This presentation will introduce a new system of acid copper technologies that have been designed to increase performance, widen the process operating window, reduce rejects and ultimately increase production capacity.

#surfin #research #automotive

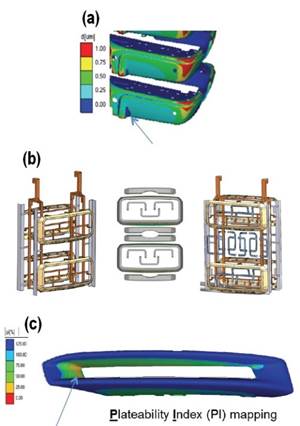

Transition from a Simple Auxiliary Anode to a Fully-developed Conforming Anode System for Plating

This paper demonstrates that the use of an elaborate CAE designed conforming anode system enables plating complex exterior automotive part designs within specification. It will be shown that the increased fixed and variable production costs that are unavoidable when operating an elaborate conforming anode system can be partially earned back by a reduction in metal consumption, and by an increased capacity due to shorter plating times.

#research #surfin #automotive

A Conversation with Darrick Gula, Bolta US

Darrick Gula is director of North America business development for Bolta US and will be the keynote speaker at the National Association for Surface Finishing’s 2018 Sur/Fin conference and trade show.

#surfin #nasf

Coventya Products Aim to Meet Surface Finishing Challenges

Coventya will highlight a variety of its latest products at Sur/Fin 2018, including Finicoat coatings, the Alumal aluminum surface treatment line and WaterCare wastewater treatment line, and 3S anode technology.

#surfin

A Brite to Highlight Solutions for Cleaning, Finishing, Wastewater Treatment

A Brite says its exhibit at Sur/Fin 2018 will encompass the three areas in which it provides products and services: cleaning, surface finishing and wastewater treatment.

#surfin

Ventilation System Designed for Energy Savings, Worker Protection

KCH Engineered Systems will display its Smart Tank Cover system at Sur/Fin 2018, designed for energy savings and increased worker protection against airborne fugitive emissions.

#surfin #energy

Cordless Plating Barrel Suited for Manual, Rack Lines

At Sur/Fin 2018, Hardwood Line will feature its battery-powered, cordless plating barrel, which can be used in manual or rack lines.

#surfin

Custom Die-Cuts Can Reduce Masking Time, Failure

At Sur/Fin 2018, Caplugs will showcase custom die-cuts designed to reduce the time, labor and risk of mask failure associated with manual masking.

#masking #surfin

QA Program Aims for Consistent, High-Performance Automotive Coatings

At Sur/Fin 2018, MacDermid Enthone will highlight its DecoKlad quality assurance program for high-performance decorative automotive coatings, which aims to ensures globally consistent performance from a network of approved applicators.

#automotive #surfin

Zinc Line Produces 60-120 Racks/Hr.

At Sur/Fin 2018, Fanta Equipment Co. will showcase its high-production, return-type automated zinc line, which is designed to produce 60 to 120 racks per hour.

#surfin #workforce development

XRF Suited for Material Analysis, Coating Thickness Measurement

Fischer Technology will demonstrate its XAN500 X-ray fluorescence instrument for coating thickness measurement and alloy analysis at Sur/Fin 2018, well-suited for quality, incoming inspection and process control of electroplated, multilayer and alloy coatings.

#measurement-testing #surfin